How to Remove Stripped or Broken Nuts

Stripped or damaged nuts can be incredibly frustrating to remove. It could drive you (bad pun intended) nuts. The important thing to remember when trying to remove a stubborn nut is to be patient.

Take your time, don’t lose your cool, and follow these tips to make removing a stubborn stuck nut much easier.

Prepping Stripped or Damaged Nuts

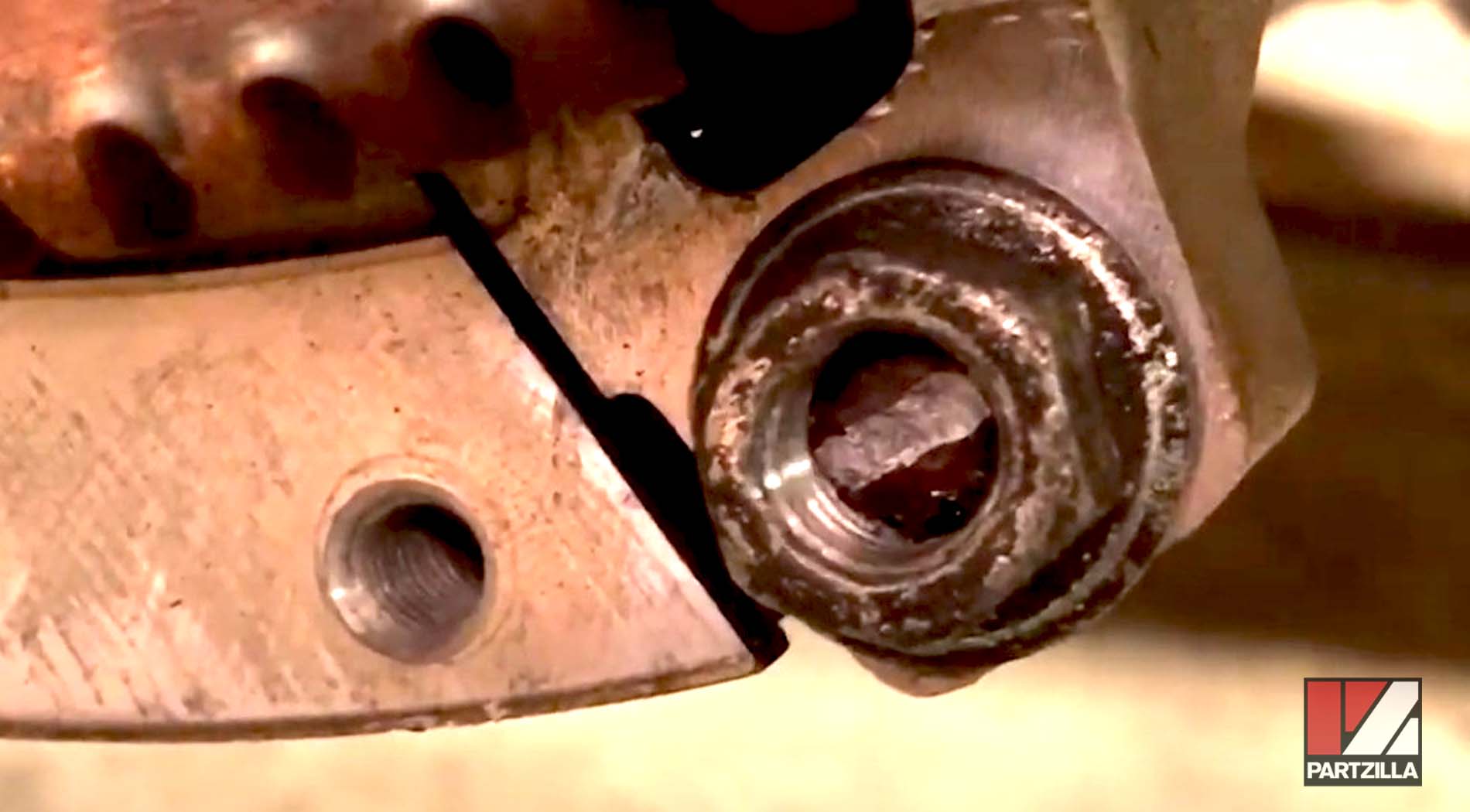

Clean the nut. Clean off as much corrosion and dirt as possible. Use a wire brush and contact cleaner if necessary.

Use penetrating oil. Apply penetrating oil to the nut. This oil is specially formulated to wick deep down into bolt threads to break down corrosion, and also acts as a lubricant that helps the nut’s removal. Leave the penetrating oil to work its way into the seized threads and dissolve corrosion for as long as possible. Let the oil sit for a couple of hours, adding a few extra drops as you do so. If possible let the penetrating oil soak into the threads for a day or two.

Strike the nut. If the nut protrudes above the thread of the fastener, hit the nut squarely on the head with a hammer to shock the threads and help break them free. If the nut is tightened below the thread of the fastener, put a hammer against one side of the nut and hit the nut from the other side with a second hammer.

Removing Seized Nuts

Use a 6-point socket. A 6-point socket (or wrench) applies more force to the thickest part of the nut because it contacts each side of the nut, not just its corners. Therefore, there’s less chance of the socket or wrench slipping and rounding the nut.

NOTE: Avoid using 12-point sockets or wrenches.

Seat the socket. Make sure the socket or wrench is fully seated over the nut to prevent the socket from slipping off the nut and to maximize the torque being applied to the nut.

Gently loosen the nut, but use your sense of feel and stop if you think the fastener might shear. If that happens, tighten the nut slightly, then untighten it again, working it back and forth to break the threads free.

Use an impact driver. This tool is normally used on screws, but can also be used on smaller nuts. An impact driver delivers a strong and abrupt combination of rotation and shock to the nut that breaks threads free.

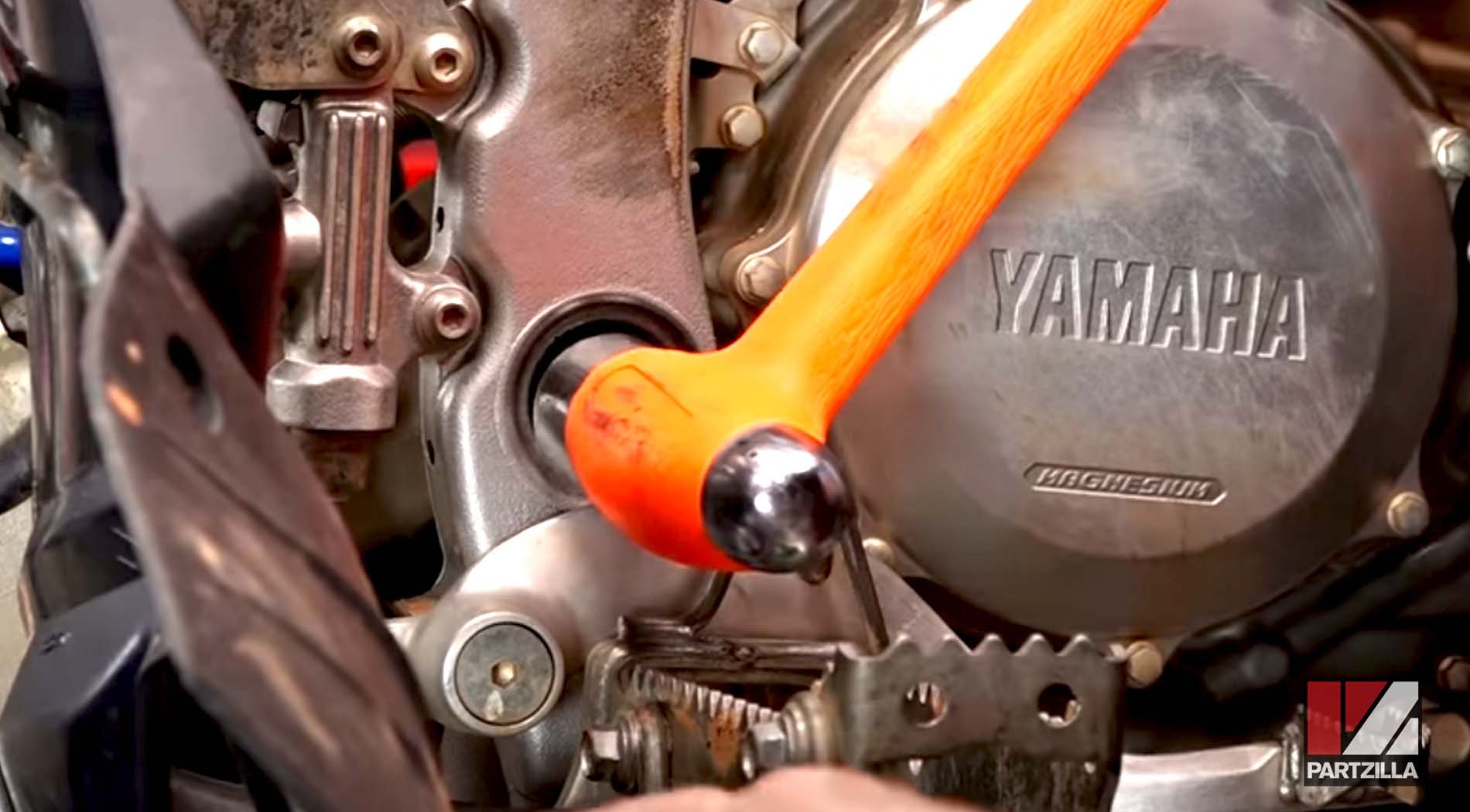

Use a breaker bar. This tool gives you greater leverage and applies more torque to the nut.

Use an impact wrench. This type of wrench delivers a series of sharp jolts and strong rotational force on the nut to break it free.

NOTE: Because of the higher chance of shearing the fastener, only use breaker bars and impact wrenches on larger nuts.

Heat the nut. Heated metal expands, so by heating the nut, seized threads may expand enough to break free. Use a butane torch (or something similar) to heat up the nut, then cool it quickly by dousing it with water.

NOTE: Because the heat will distort the nut and the bolt it’s attached to, both will need to be replaced. Never use a torch near flammables or materials that may catch fire such as plastic or rubber gaskets.

Use a nut-splitter. This tool locks around a nut and drives a chisel into it until it splits, after which it can easily be removed.

Cut the nut. Put a hacksaw or a small cutting tool such as a Dremel against the side of the thread and cut down through the nut to remove it.

Grind the nut. If the nut is attached to a bolt and that bolt can be removed and replaced once the nut’s removed, use an angle grinder to grind away the nut (and the portion of the bolt within it) completely.

Removing Damaged Nuts

Cut new edges. Use a hacksaw or small cutting tool to cut a flat edge on either side of the nut. Now you can grip the nut with an adjustable wrench and rotate it.

Weld on a new nut. If the nut protrudes above the thread of the fastener, weld a new nut to the damaged nut. Allow the weld to cool, then put a socket or wrench on the new nut and remove the new/old nut combination.

Prevent Nuts From Seizing

Never overtighten nuts when torqueing them down. Always torque nuts to the correct specification using a torque wrench, and apply anti-seize lubricant to threads before tightening them.

NOTE: Anti-seize lube is only recommended for certain fasteners. Consult your vehicle’s service manual to see whether anti-seize lube is usable on a particular fastener.

Stripped and damaged nuts are a royal pain to remove. So are stripped screws. Watch the video abovefor tips on how to remove a stripped screw.