Motorcycle and ATV Clutch Inspection and Care Tips

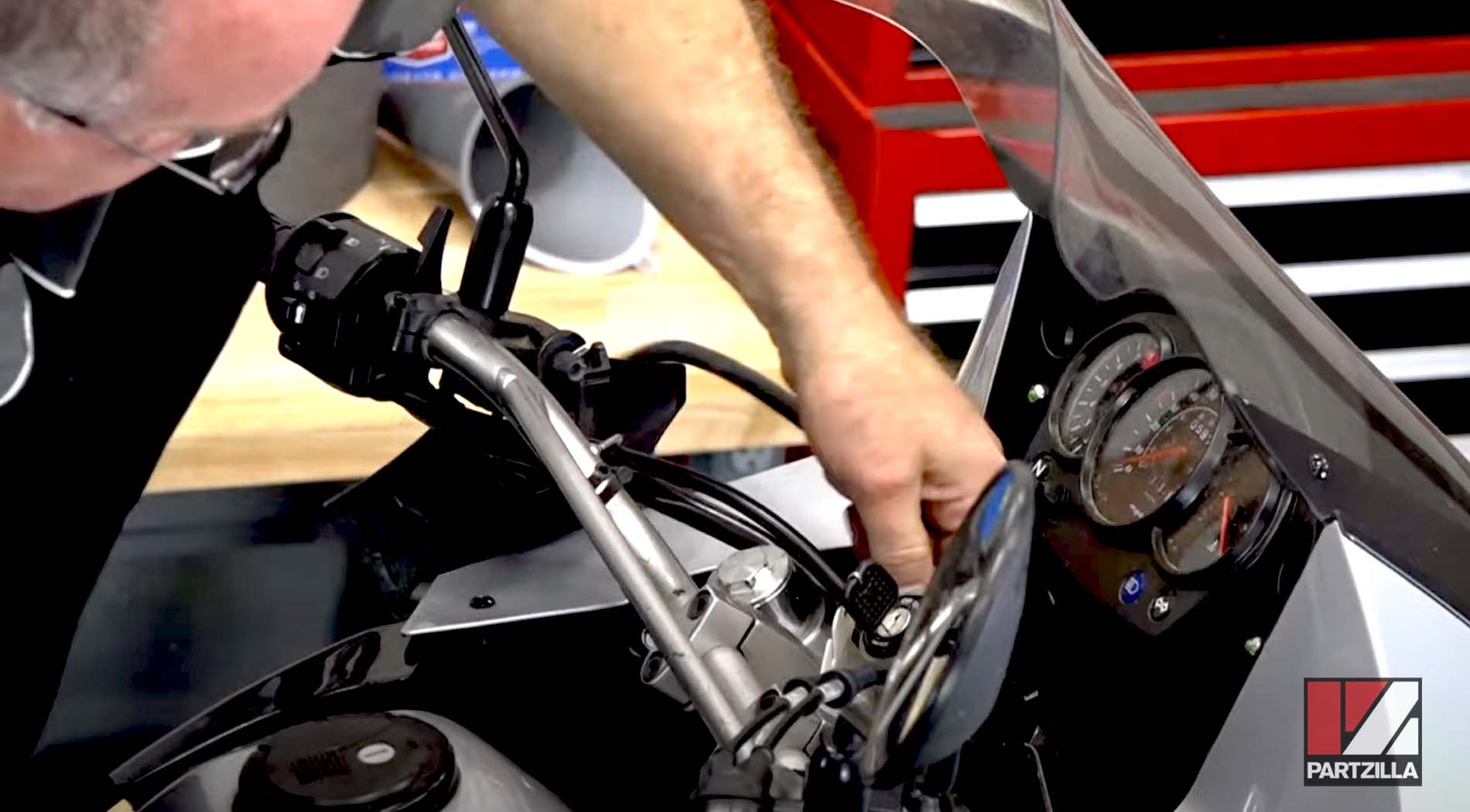

The clutch in your powersports machine’s drive system links the motor to the transmission, and maintaining it is essential to your motorcycle or ATV’s performance.

Here are several ways to inspect and maintain the clutch on your powersports machine.

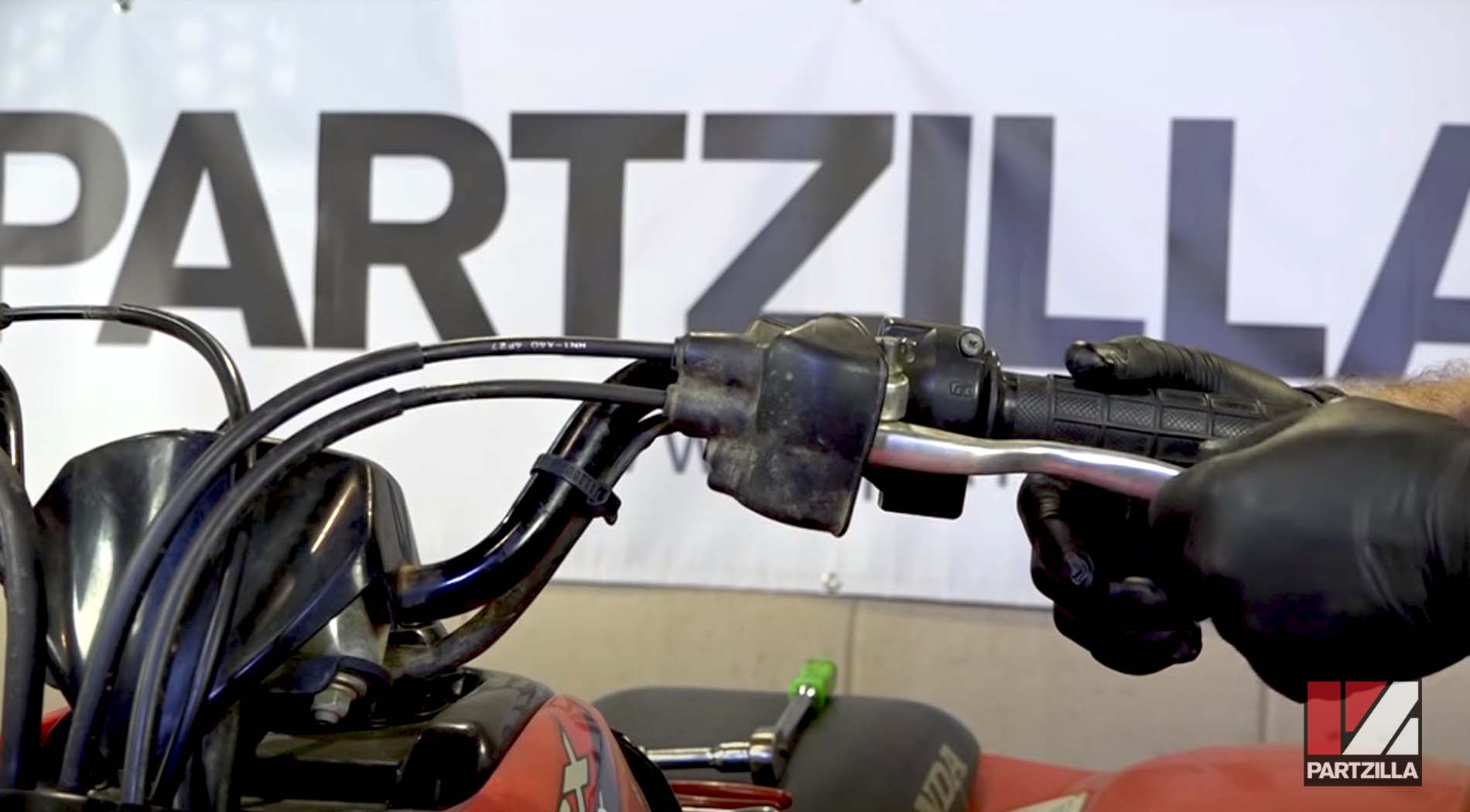

Adjust the Clutch Cable and Lever

Too little or too much play in the clutch lever can both lead to clutch problems. When there’s too little play, clutches will sometimes be partially engaged, causing them to wear prematurely.

With too much play, the clutch can be difficult to completely engage. Typically, you’ll want about a half an inch of play in the cable if you’re measuring at the outer end of the cable. Many clutch types have two adjustment points:

Fine Adjustment

At the lever, the fine adjustment allows you to fine-tune the amount of play in the lever. But eventually, you’ll run out of room to adjust there.

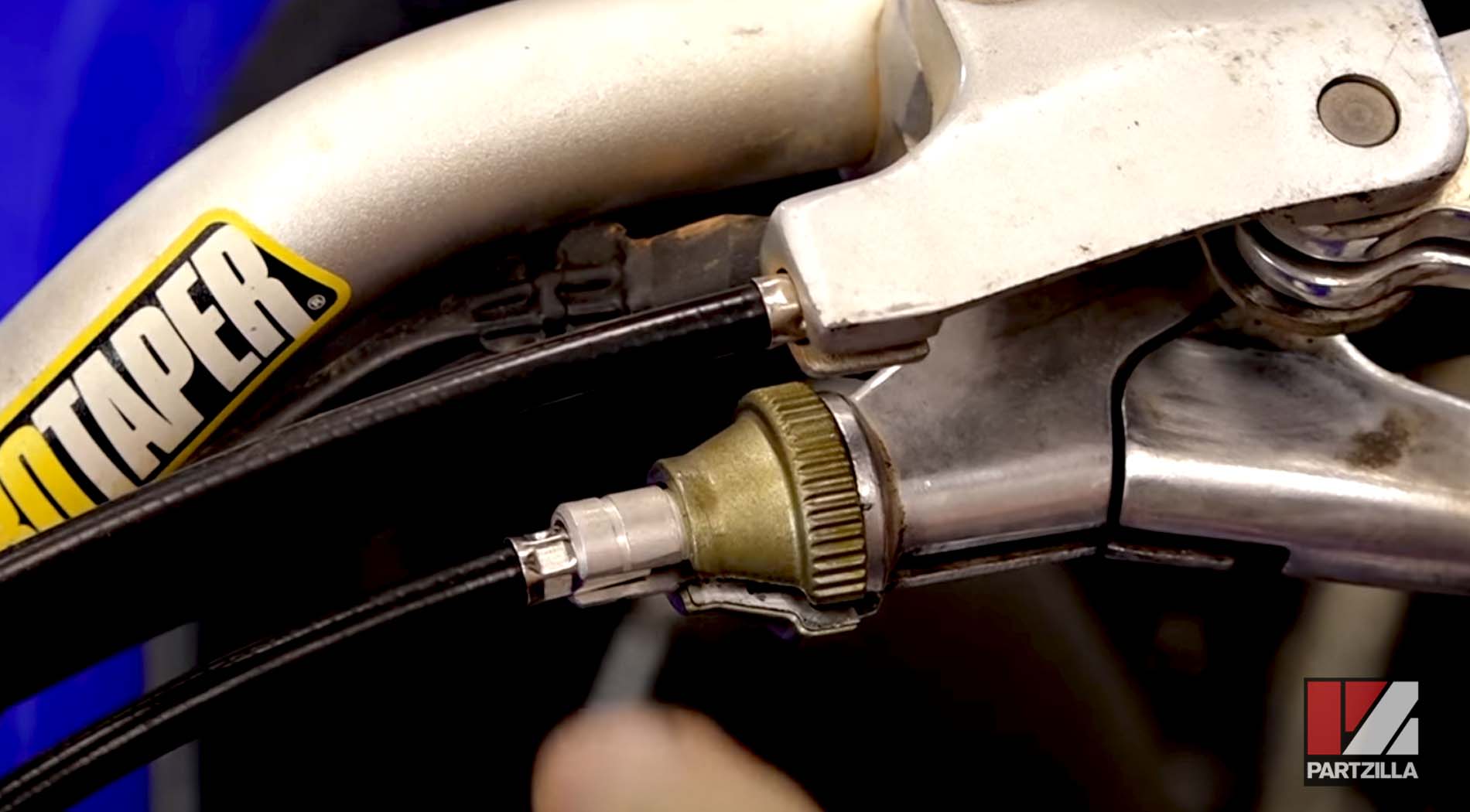

Coarse Adjustment

Down at the other end of the clutch cable, at the clutch itself, is the coarse adjustment, which allows you to make big swings at the play in the cable.

Replacing the Clutch Cable

A clutch cable will eventually stretch and run out of adjustment. When this happens, you’ll need to replace the clutch cable on your motorcycle or ATV.

This involves disconnecting the clutch cable at the lever end and the clutch end, then removing the cable and installing a new one. In many cases, you can use electrical tape to attach the new cable to the old cable at the clutch end and then pull the old cable out, dragging the new cable into the correct route through the frame.

How to Inspect the Clutch on a Motorcycle or ATV

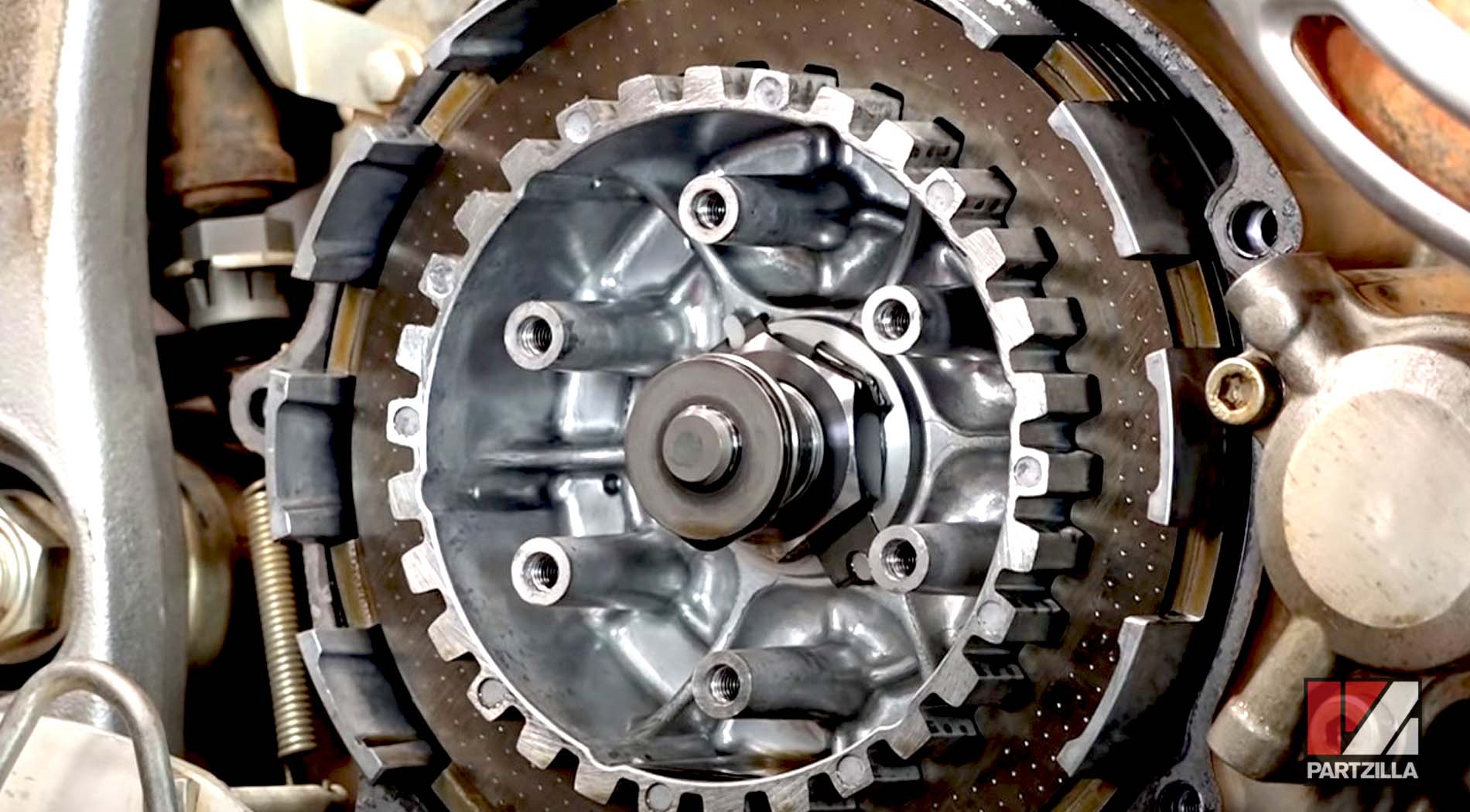

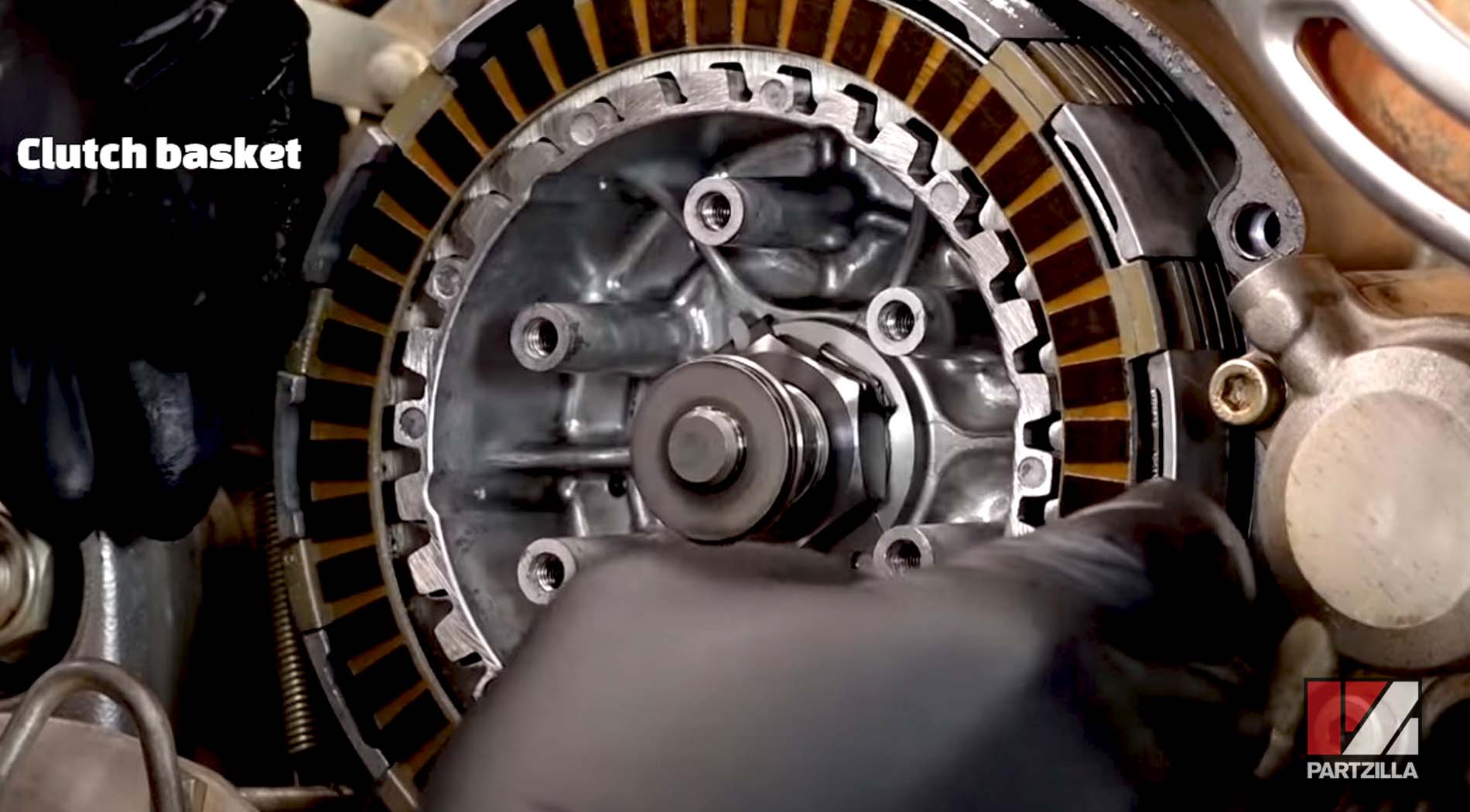

Your machine’s clutch is comprised of an outer basket connected to the crankshaft and an inner hum connected to the transmission’s input shaft.

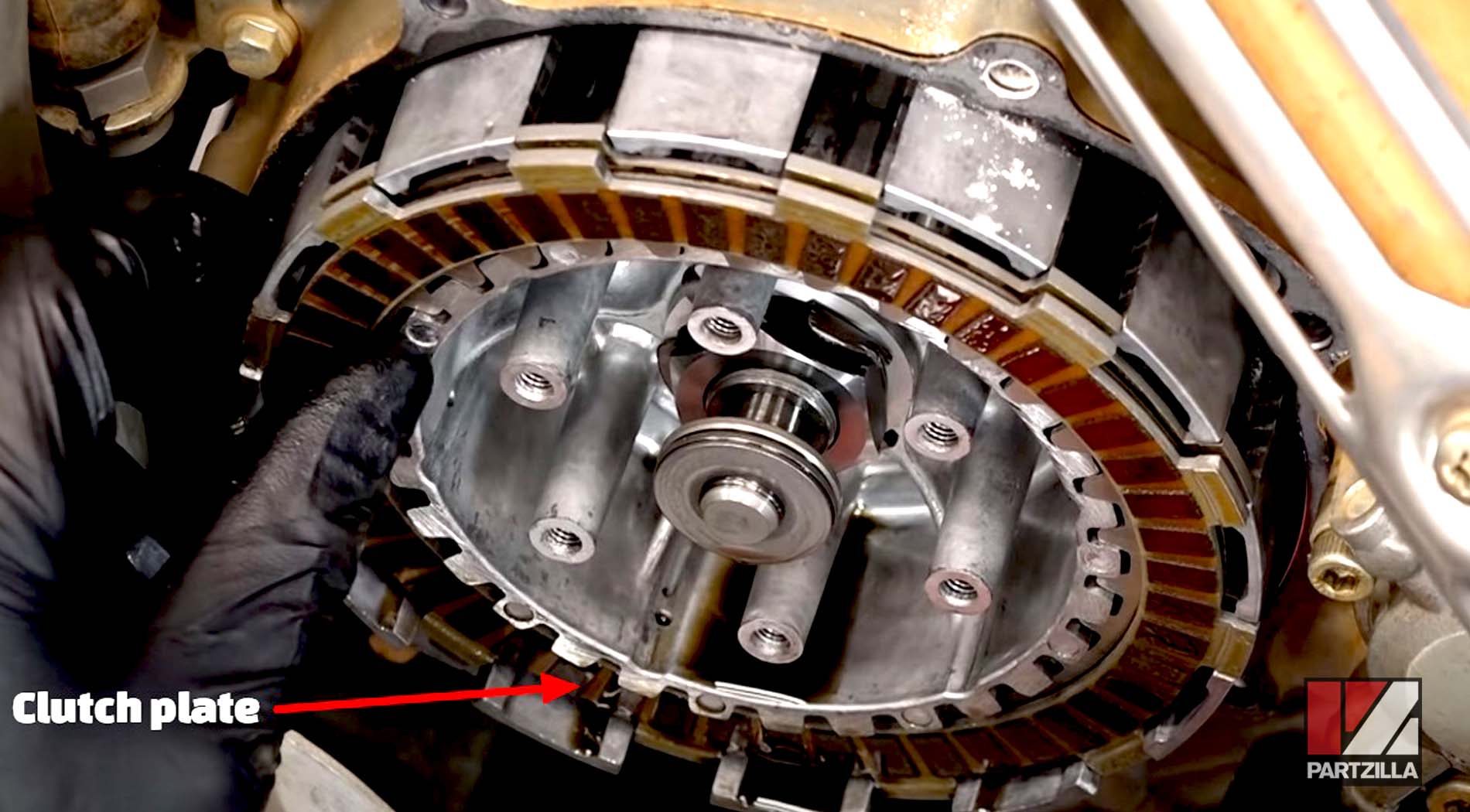

The outer basket is turned by the crankshaft, and the inner hub turns the input shaft and from there, the gears in the transmission. Between the turning of the clutch basket and of the hub, a set of friction plates interact with varying degrees of pressure, which can allow them to spin freely past each other or turn each other as pressure is increased.

When the clutch isn’t engaged, slipping plates can reduce power, since the full rotational force of the crankshaft is not being transferred to the hub and transmission. When you feel this reduction of power, that’s a sign that the plates are wearing. Worn, overheated clutch plates have a distinctive smell that’ll tell you when it’s time to inspect them.

Worn friction plates can be measured to determine how much of the friction material remains on the plate. Drive plates, the metal plates in the clutch basket, look discolored when worn.

On the clutch basket itself, look for notches in the channels that hold the friction and drive plates. The plates should slide freely inside the channels. You shouldn’t sand down any notches or imperfections in the baskets, since they’re built to exacting specifications and really tight tolerances.

Another thing to inspect is the clutch springs. They rarely fail, but as they’re subjected to thousands of heat cycles, the metal in the springs can fatigue. As they do, they lose their stiffness and may not fully engage the plates. If you’re pulling the clutch lever and it doesn’t have the resistance it used to, the springs are likely done and it’s time for a clutch inspection.