How to Lap the Valves on an Engine

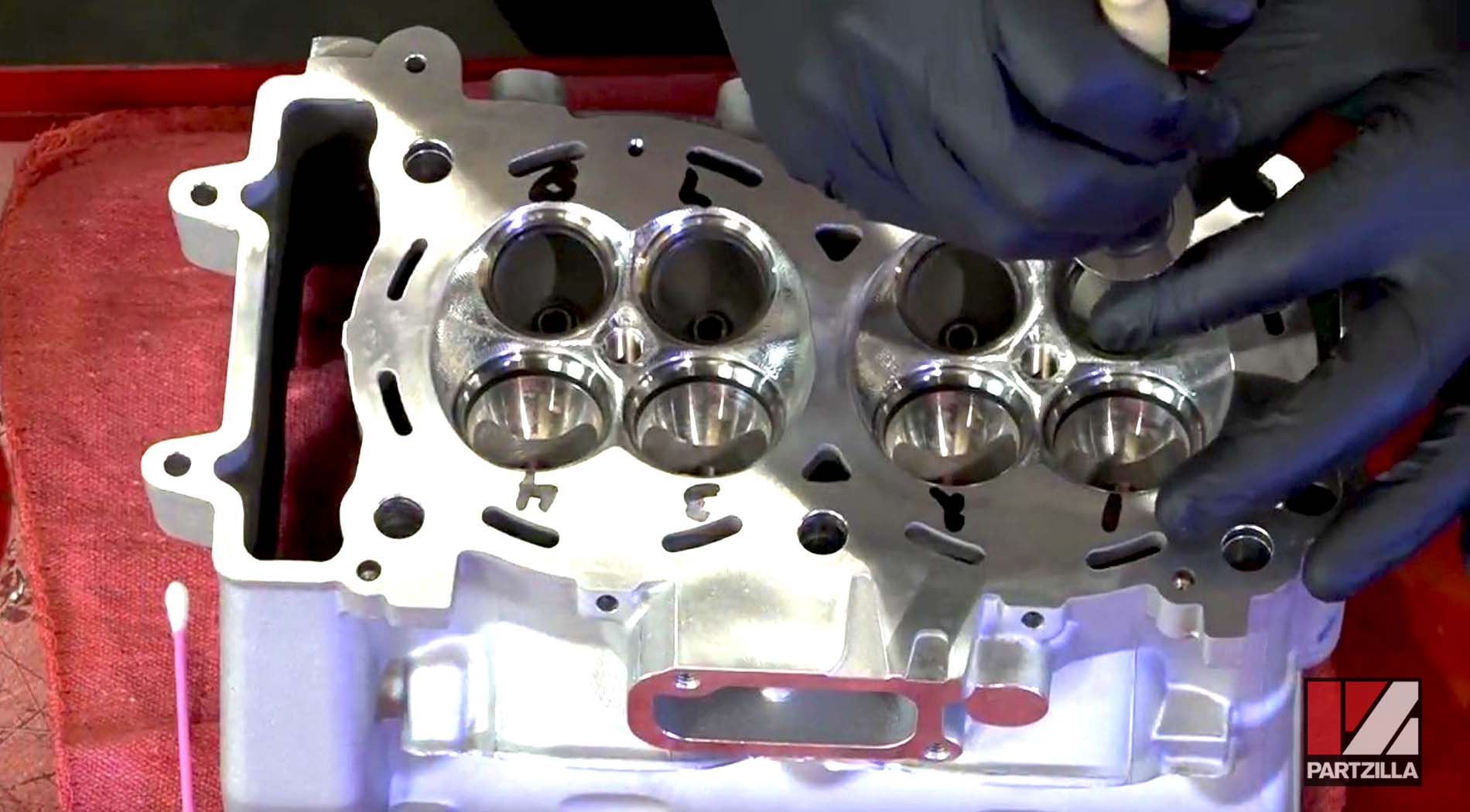

A top end rebuild should help better the performance side of a machine, provided the valves and the valve seat fit properly. A good seal keeps the pressure and the power in the cylinder where it belongs.

Watch the video above and follow the steps below to learn how to lap the valves on an engine.

Tools and Supplies – Engine Valve Lapping

- Lapping tool

- Valve grinding or lapping compound

- Prussian Blue

NOTE: We lapped the valves on the engine of a 2012 Polaris RZR 900XP, but the process is the same or similar for all engines.

If you’re using a new head and valves, things should line up nicely. Prussian Blue gives you a chance to check. It’s a dye that shows you where two pieces of metal make contact. Here’s how to make sure the valves are getting a good seal.

Checking Valve Seats

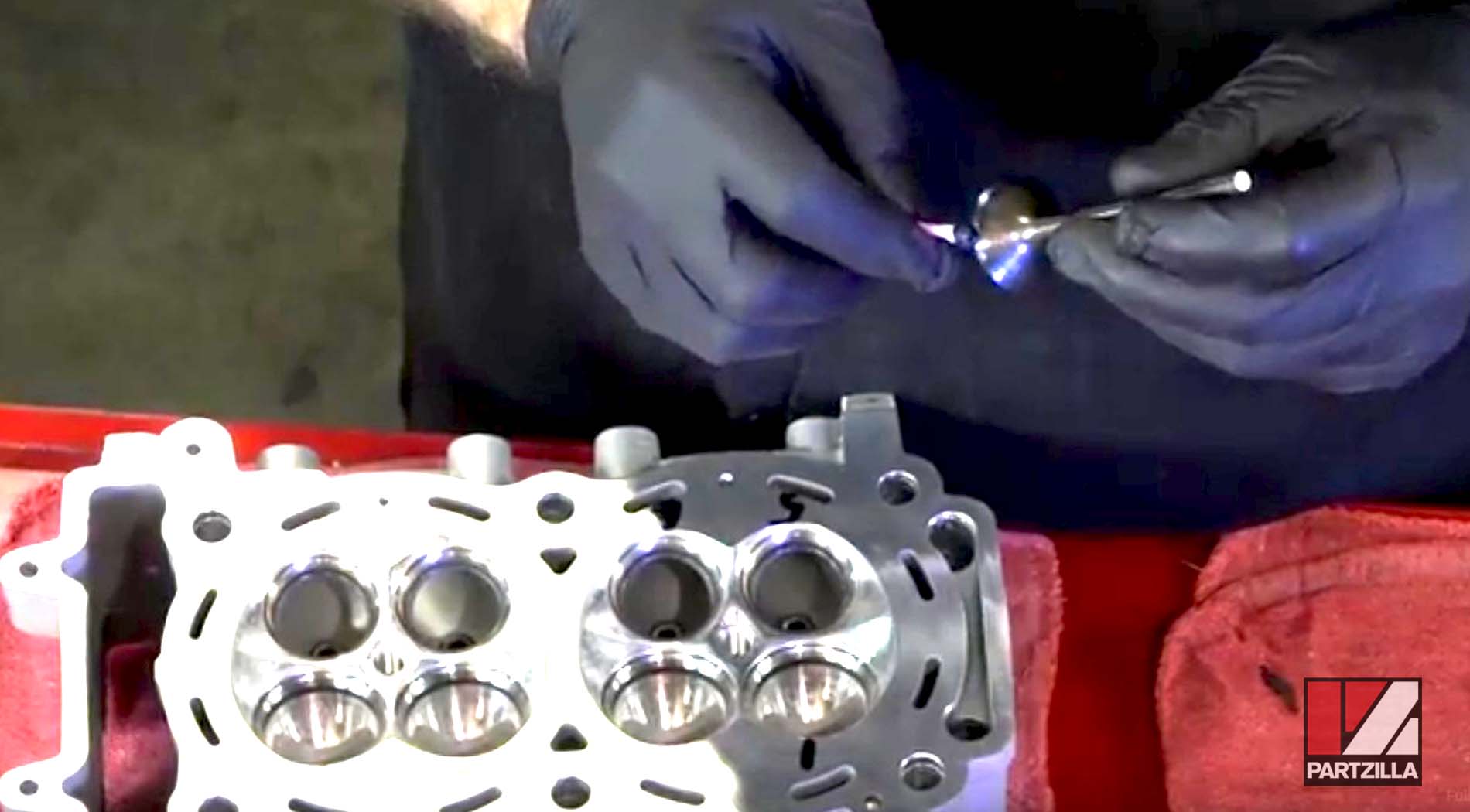

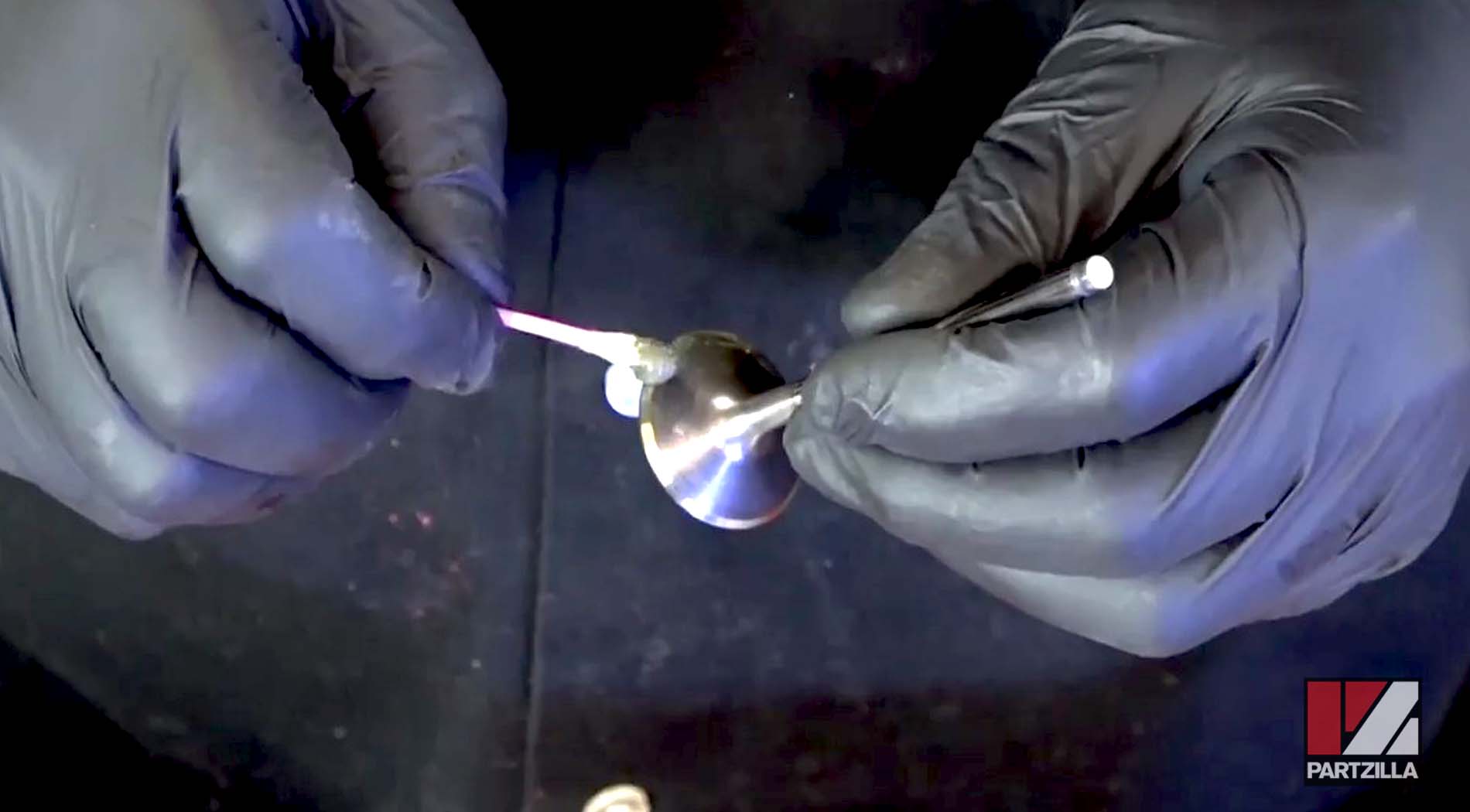

Step 1. Coat the edge of the valve with Prussian Blue.

Step 2. Position the valve in the cylinder head.

Step 3. Rotate the valve in the seat using the lapping tool or a quarter-inch piece of fuel line slid over the valve stem.

Step 4. Remove the valve from the cylinder head.

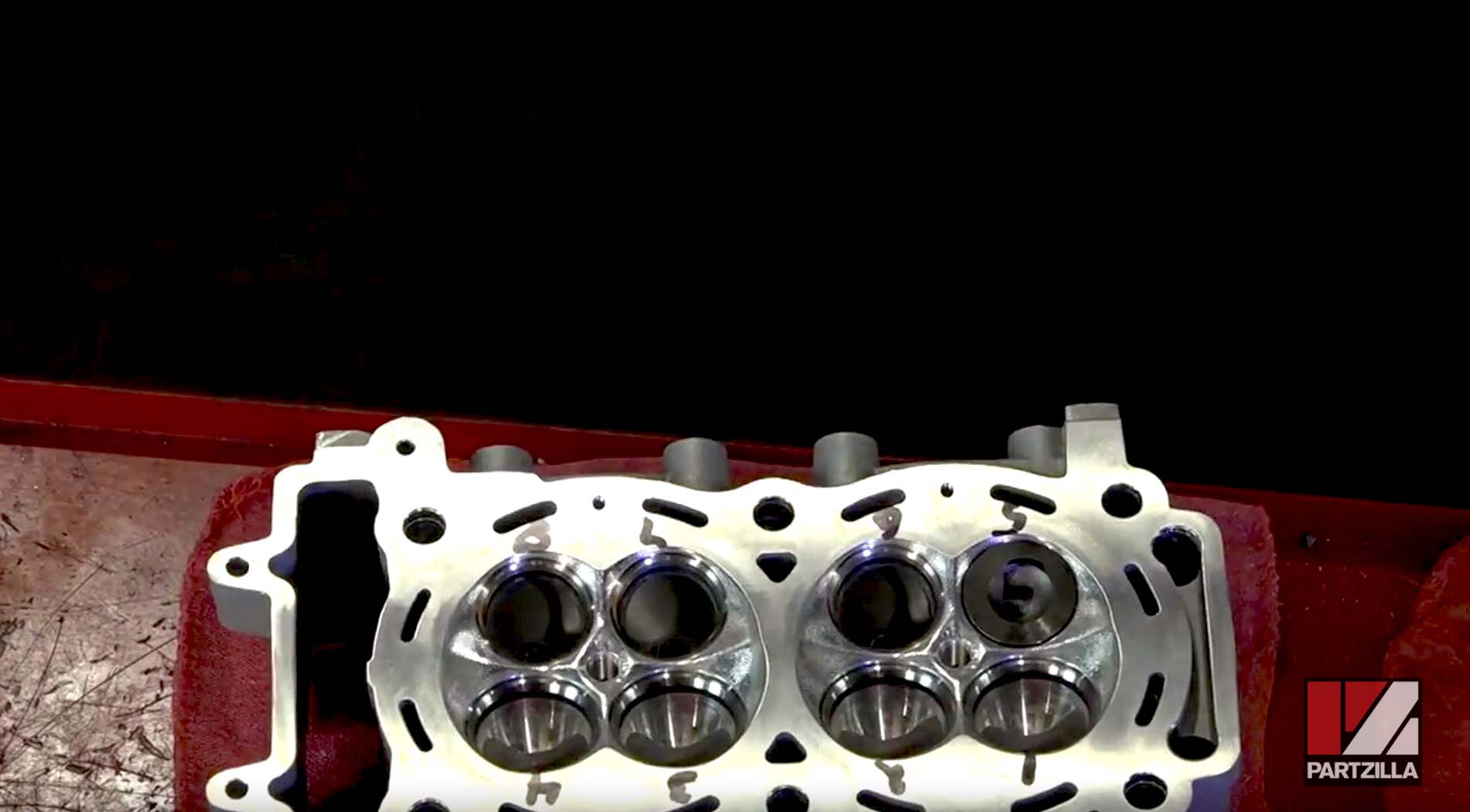

Step 5. Check for a thin line of blue dye completely around the circumference of the valve seat.

Once you get the Prussian Blue cleaned off the valve and the head, you’re ready to start lapping. The valve grinding or lapping compound is just a grease with an abrasive in it. Here’s how to use it.

Using a Valve Lapping Tool

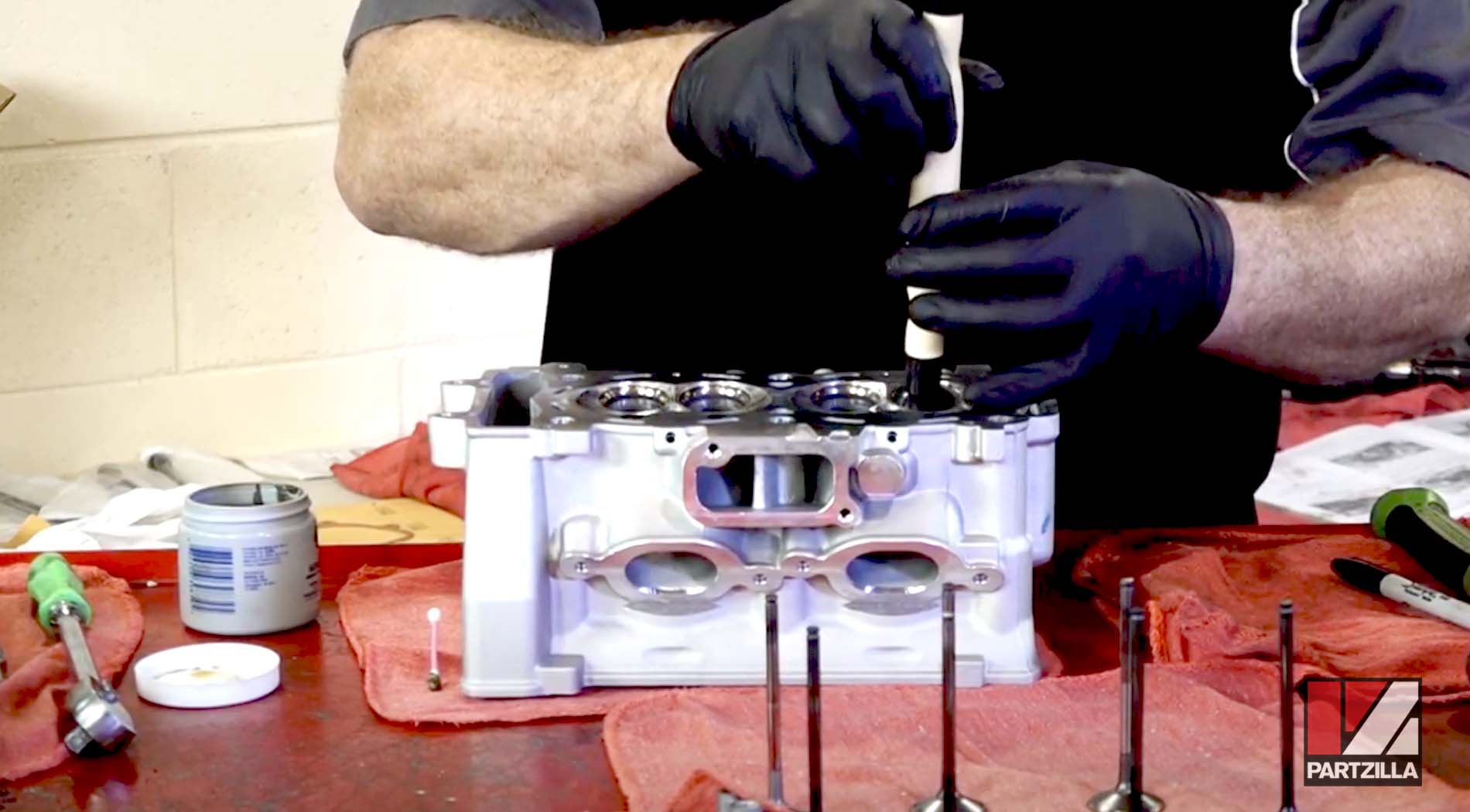

Step 1. Apply a little lapping compound around the edge of the valve.

Step 2. Apply some oil on the valve stem since you’ll be applying pressure to the valve.

Step 3. Re-insert the valve, taking care not to get any of the lapping compound on the valve stem.

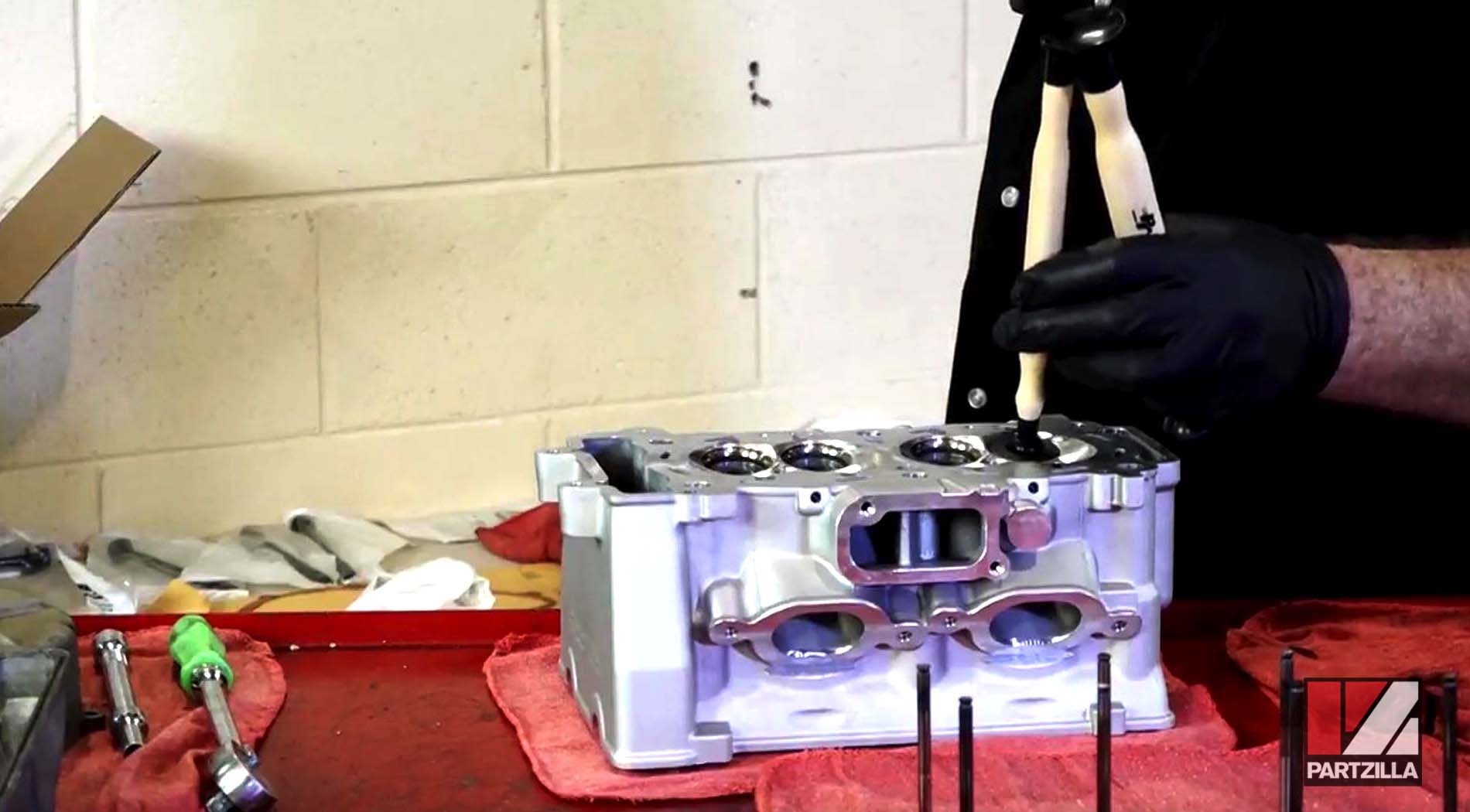

Step 4. Attach the suction cup end of the lapping tool to the face of the valve, then rub your hands back-and-forth to rotate the valve in the head.

NOTE: It’ll sound gritty at first, but the sound will fade as you continue.

Step 5. Use the lapping tool to lift the valve up to allow more of the lapping compound between the valve and the head. Repeat until the grinding fades.

Step 6. Pull the valve out.

NOTE: Make sure you remove all of the lapping compound from the components, as it can cause serious damage to the engine.

Repeat the process for all the valves — intake valves and exhaust valves — on your engine.

Lapping the valves is an important part of a complete top end rebuild. And while we did this on a Polaris RZR 900 XP, the basics remain the same: a little compound, insert the valve, spin the valve in the head, remove and clean.

Ready to see the actual top end rebuild for the valves that were lapped? Watch the video above to see how to rebuild the top end of a Polaris RZR 900 XP.