Do I Really Need Assembly Lube?

Engine parts require lubrication to work properly, and they need to be lubricated from the start during the process of an engine being put together, which is why assembly lube is so important to any build.

While you’re building or modifying an engine, assembly lube works to protect new and existing parts from wear at start-up. Some people believe assembly lube is unnecessary, and that all you need is regular motor oil or gear oil to lubricate parts during an engine build. With that in mind, here are some things you should know about engine assembly lube.

What is Assembly Lube?

Engine assembly lube is made with a combination of oil and tackifiers or grease. This substance is designed to remain in place and reduce friction after it’s applied. Assembly lube is stickier than motor oil, and contains corrosion inhibitors in its formula to protect engine surfaces.

What Does Assembly Lube Do?

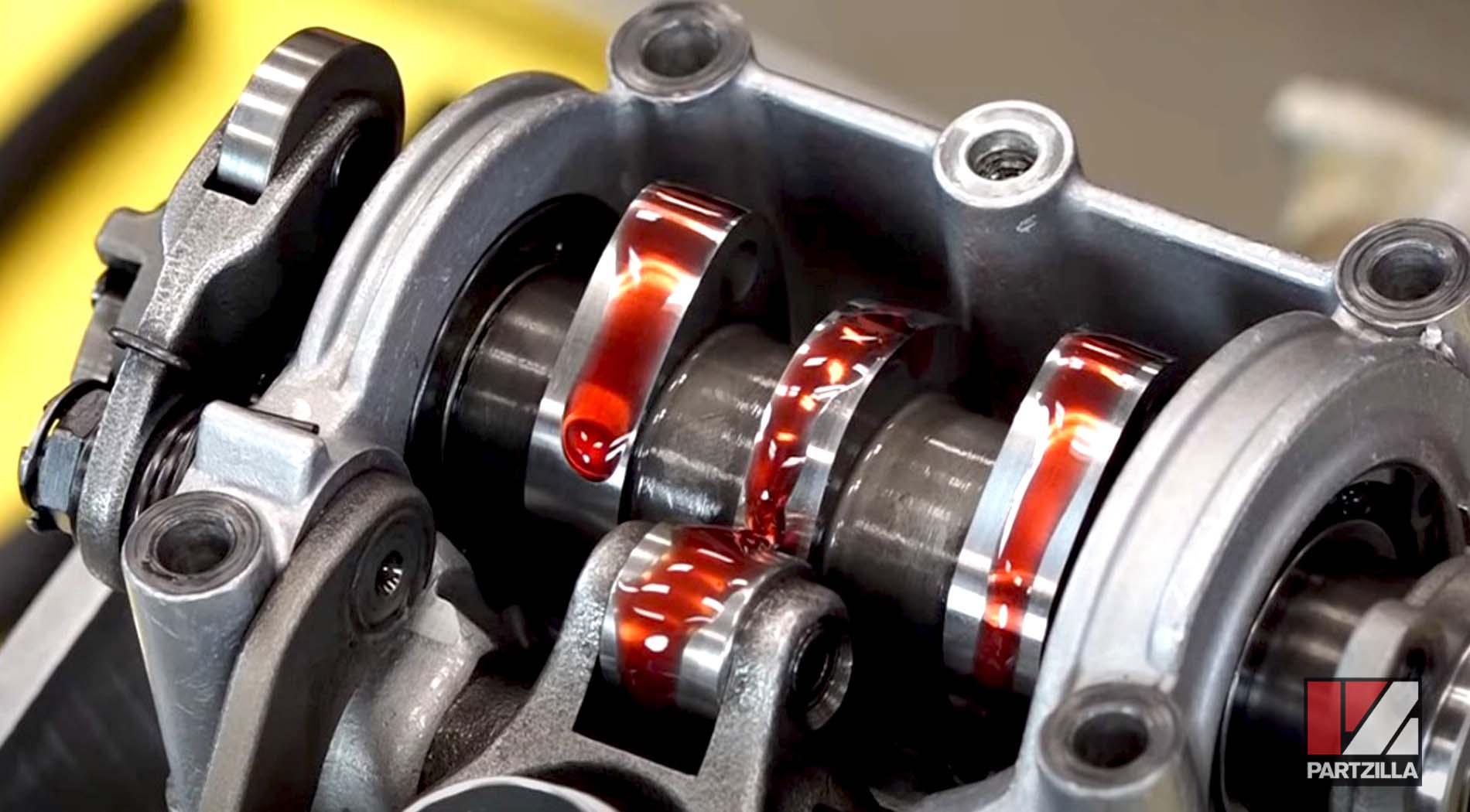

Assembly lube sticks to metal parts, and aids in assembling (hence the name) engine parts together. It also provides protection after the parts it’s been applied to have been assembled and start moving.

The thickness of this lubricant helps it stay intact for the time needed to complete an assembly. While the engine is running, it provides lubrication for metal parts until the oil pressure builds up on startup and the oil starts to flow. Once that happens and the engine oil starts doing its job, the assembly lube dissolves into the oil. Its main purpose is to protect moving parts until the engine oil kicks in and does its job.

Assembly Lube Functions

- Prevents metal parts from coming into direct contact with each other during the initial start-up of the engine.

- Reduces friction and wear during the initial start-up, and the time it takes for parts to break-in properly.

- Helps keep mechanical parts clean and corrosion-free by providing a protective layer of lubrication to metal surfaces.

Assembly lube can be applied to any new or modified engine parts that can wear out during the start-up phase of an engine. These parts include:

- Pistons and rings

- Timing chains

- Valve stems

Once the engine starts up and the pressure builds enough to get the oil flowing, the assembly lube dissolves into the oil.

Can’t You Just Use Oil?

Why not just use a thick oil instead? Because assembly lubes are more like grease, which is designed to stay in place. However, assembly lube is meant to disappear into the oil once it’s done its job. The oil system isn’t yet fully pressurized upon startup, and so oil might not reach all of the engine parts right away.

Assembly lube is an extra layer of lubrication with the right amount of viscosity that’ll hold, where oil may not, to ensure the parts have plenty of lubrication right from the start. Having assembly lube in place protects components that experience friction until the engine oil takes over. It’s essentially a primer for motor oil.

Which Assembly Lube Should I Use?

The best assembly lube for your engine is whatever the manufacturer recommends. The same goes for how and where to apply it.

There are several types of assembly lube available, but the two most common types are:

- Petroleum-based lube: Provides short-term protection while assembling an engine. These lubes are inexpensive and good for engine start-ups, but can break down over time and can be messy to deal with.

- Synthetic lubes: Provide longer-lasting protection than petroleum-based lubes. Synthetic assembly lubes are more resistant to heat and oxidation, and are less messy to apply and clean up.

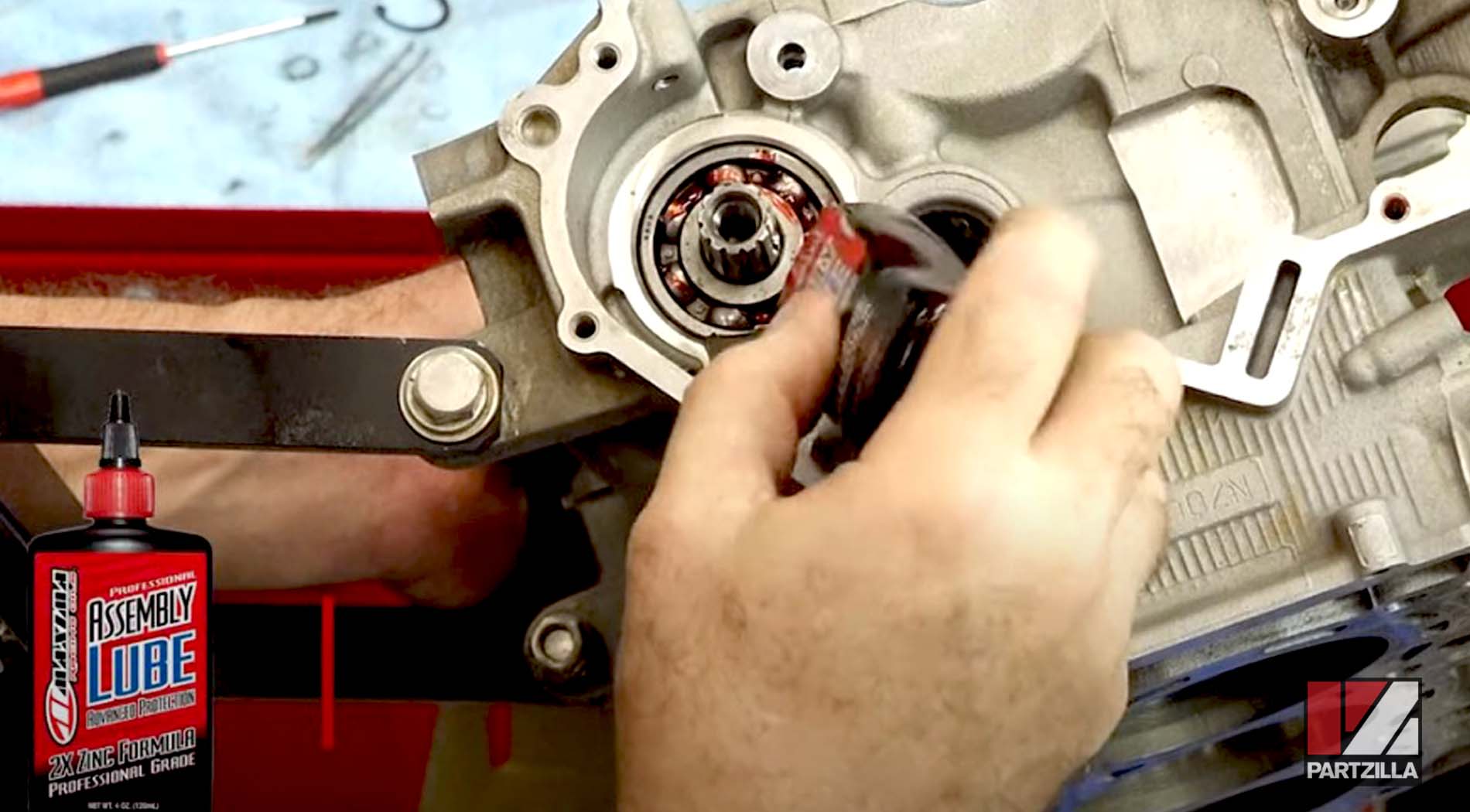

When applying assembly lube for an engine build, always consult the manufacturer’s specs to determine the proper amount to apply for each part you’re going to use it on.

Note that excessively thick assembly lubes can clog oil passages. So can applying too much lube, which can also lead to poor engine performance by increasing friction or causing parts to stick. Make sure you clean all components thoroughly before applying assembly lube so that it adheres properly.

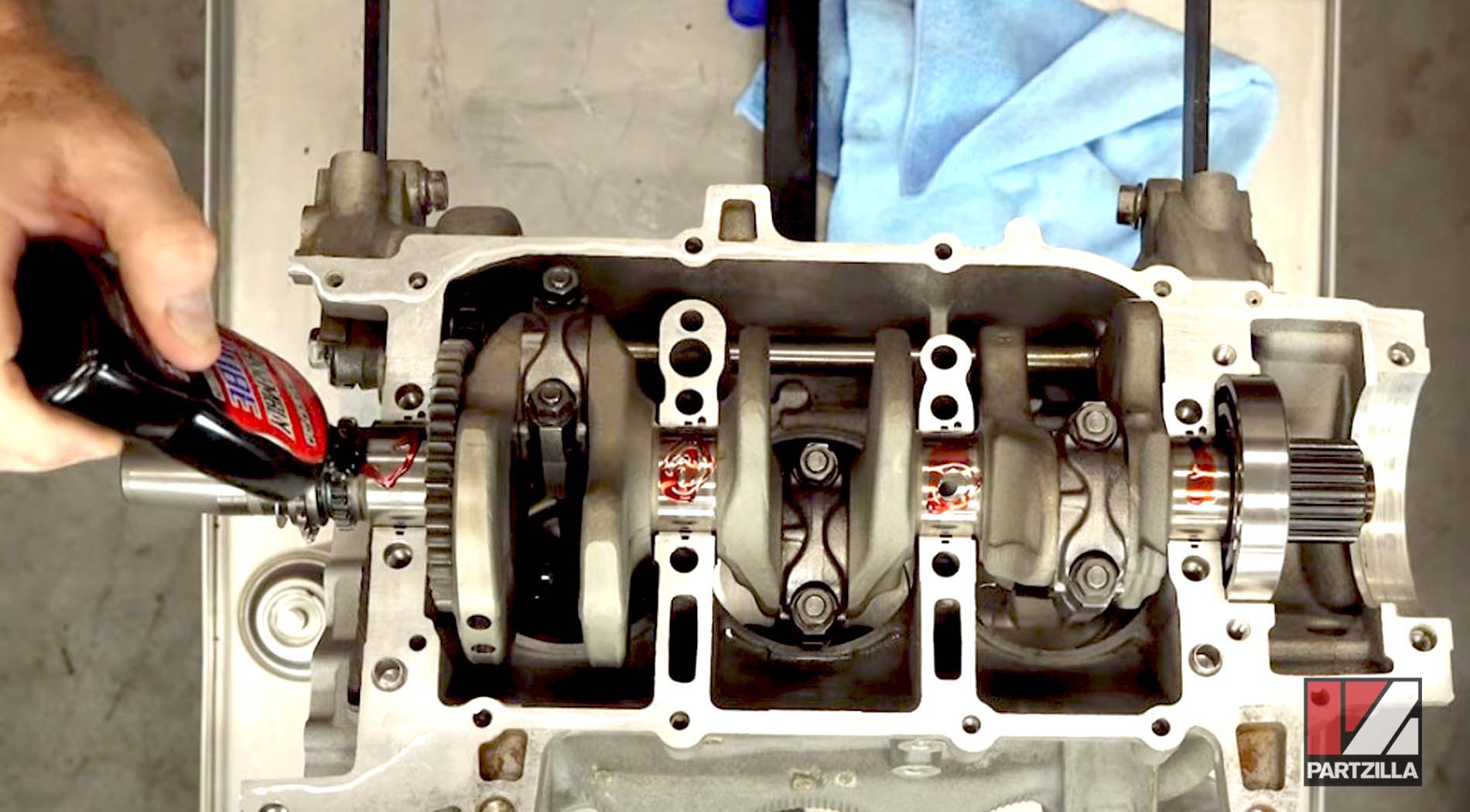

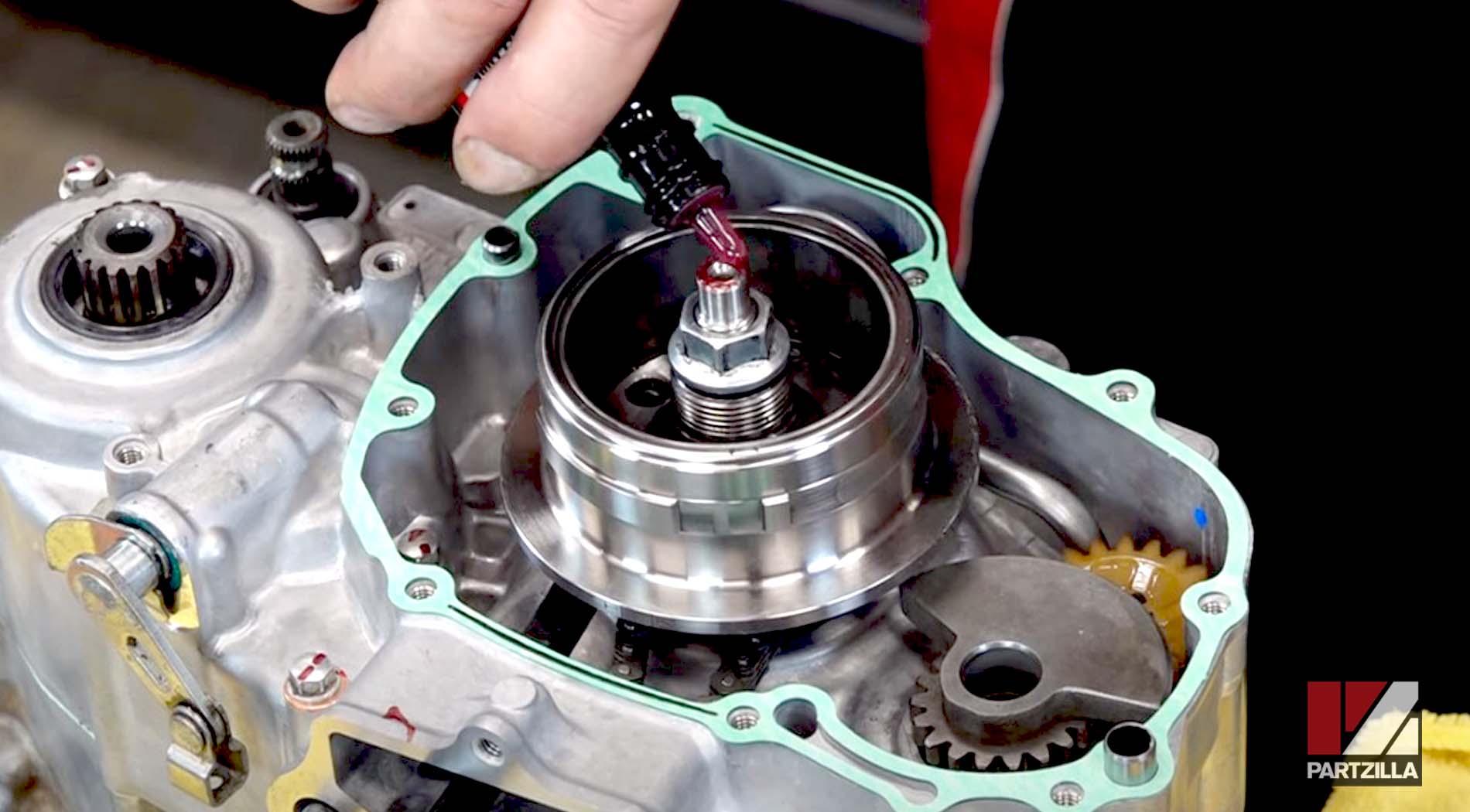

Partzilla’s resident powersports pro John Talley has used assembly lube on many of his motorcycle, ATV and UTV engine rebuild projects for our YouTube channel. Check out a few of those engine rebuilds below.

Honda CRF450 Top End Rebuild - Motorcycle

Yamaha Raptor 700 Complete Engine Rebuild - ATV

Yamaha YXZ1000R Bottom End Rebuild - UTV