How to Prevent Engines from Blowing Up

One of the most frequently asked questions among powersports vehicle riders and enthusiasts is “Why do engines blow up?” The answer to the question is usually simple: because it wasn’t properly maintained.

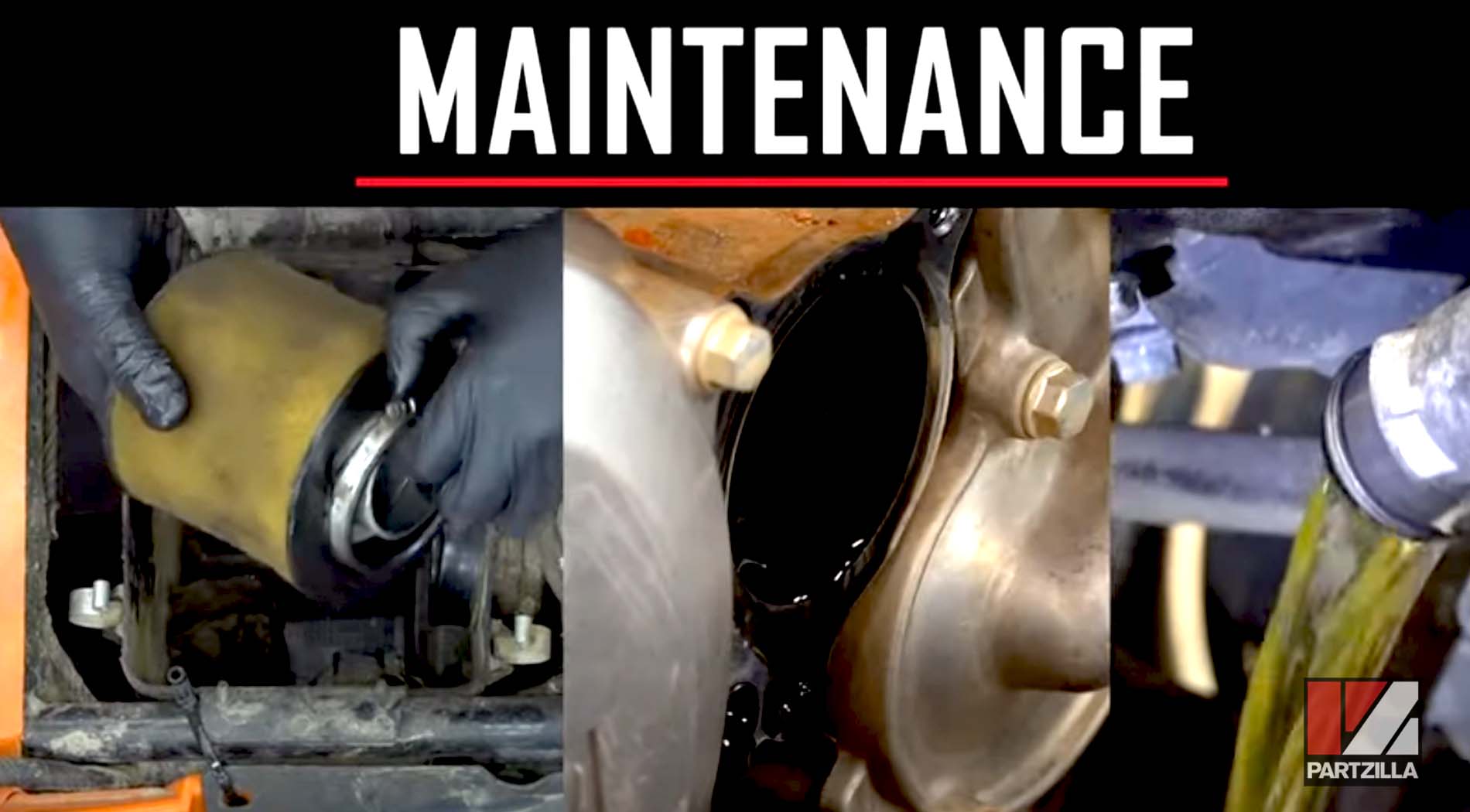

A lack of basic routine maintenance is the #1 killer of engines, accounting for about 90% of all engine blow-ups. We’re not talking about complex stuff like top-end rebuilds, but the absolute most basic maintenance everyone who owns a powersports vehicle should be doing on a regular basis.

Routine Maintenance to Prevent a Blown Engine

The three main basic areas of maintenance that, when completely ignored or mishandled, can lead to an engine blowing up are:

- Lubrication system

- Air intake system

- Cooling system

Lubrication System Maintenance

When the engine oil is left in the motor too long, it breaks down and fails to lubricate all the moving parts effectively. Lack of lubrication leads to bearings wearing out faster; valves not being able to move as freely; abnormal camshaft wear; and so on. Eventually the wear on these and other parts causes them to start binding, leading to a bearing spinning or a valve hitting a piston and then, you guessed it: engine failure.

Replace the engine oil and the oil filter on a regular basis to prevent engine blow-ups. If the owner’s manual says to change the oil and filter every 3,000 miles, do it. Don’t wait another 1,000 miles or try to save a few bucks by skipping the oil filter change.

Air Intake System Maintenance

A dirty air filter prevents the engine from getting the air it needs, while a worn or damaged filter lets dirt and debris into the engine. The engine will run rich with too little air, which leads to overheating, and causes internal parts to fatigue until something breaks. Dirt bypassing a worn air filter will enter the engine, where it acts as an abrasive on the piston rings, pistons and cylinders, rapidly wearing them out. Whether it’s from repeated heat fatigue or abrasion, a moving part breaking within the motor usually results in an instantly blown engine.

If you're going to replace or clean the air filter, follow the owner’s manual or manufacturer’s recommendations, and do it even more often than what’s recommended if you ride your machine frequently in harsh conditions.

Cooling System Maintenance

When it comes to basic engine maintenance, the cooling system is perhaps the most overlooked of all. It’s not uncommon for an engine to have the same coolant it had when it rolled off the production line. The chemicals in old coolant break down over time and become acidic, which corrode the cooling channels within the engine block. Old coolant can eat its way into engine parts it’s not meant to reach, such as the oil system and combustion chambers. When that happens, expect the engine to blow sooner than later.

Drain and replace the engine coolant on a regular basis. The rule of thumb is to change the engine coolant every two years, but as always, follow your vehicle’s owner’s manual for how often it should be done.

Additional Ways to Prevent a Blown Engine

If 90 percent of engine failures are due to a lack of routine maintenance, the remaining 10 percent is generally a result of exceeding the performance capability of the engine. Blowing out an engine by pushing the machine beyond its limits usually happens in two ways:

Over-Riding

An engine can fail due to a mistimed gear change or from willfully pushing the motor past it’s red-line limit. When it goes over the red-line limit, the engine’s RPM surpasses the speed at which the valve springs can retract the valves. This results in the valves and pistons colliding, a valve being pushed through a piston and the engine blowing up in spectacular fashion. It’s not uncommon for riders to put undue stress on the engine by over-revving it while trying to get every ounce of speed possible. Don’t try to ride like a MotoGP rider if your skill level isn’t up to par, and respect the red line on the tachometer. Ride within your limits and your machine’s limits.

Exceeding the Engine’s Parameters

An engine can be forced to perform beyond its capabilities, either by repeatedly taking the engine to its absolute RPM limits, or by modifications made to squeeze more performance out of the motor. When a motor is pushed past the limits it was designed to operate within, a problem is bound to happen. The engine mapping controlling the air-fuel mixture can be compromised, leading to lean running and a hole burned in the piston. Or the engine might overheat and either blow a head gasket, or have a piston seize in a cylinder and force a connecting rod out through the engine block.

Never max out the motor on your motorcycle, ATV or UTV when riding. If you want to add some performance parts, make sure they’re compatible with your ride’s exact make and model, and if possible, purchase a complete performance package instead of disparate parts.