Troubleshooting Common Motorcycle Wiring Mistakes

Sooner or later every motorcycle owner encounters problems with the electrical system on their bike. How severe the electrical issue mainly comes down to how well the motorcycle has been serviced.

We often think about components such as batteries, starters, stators and regulator-rectifiers when it comes to electrical issues with motorcycles, but what about the wiring that connects these and other components? Here’s a look at some common motorcycle wiring mistakes and how to troubleshoot them.

Typical Causes of Wiring Problems on a Motorcycle

Although parts of a motorcycle’s electrical system such as a stator or a regulator/rectifier can fail, wiring problems are often the culprit behind electrical issues.

Here are the three of the most common motorcycle wiring problems:

Motorcycle Wiring Problem 1: Bad Connections

The connection joining a wire and its source/destination, or the connection between two wires, is loose or corroded. Either way, the electrical current or signal passing through the connector will be weakened or halted completely.

Motorcycle Wiring Problem 2: Short Circuit

The wire is shorting to ground and the electrical current or signal is not reaching its intended destination.

Motorcycle Wiring Problem 3: Broken Wire

The wire is damaged, causing the conductive wire within the protective jacket to fray or break completely. This causes intermittent or no electrical current or signal reaching its intended destination.

Common Motorcycle Wiring Mistakes

While sometimes wiring fails due to age, usually the problem is caused by errors made by the owner or other person who worked on the bike.

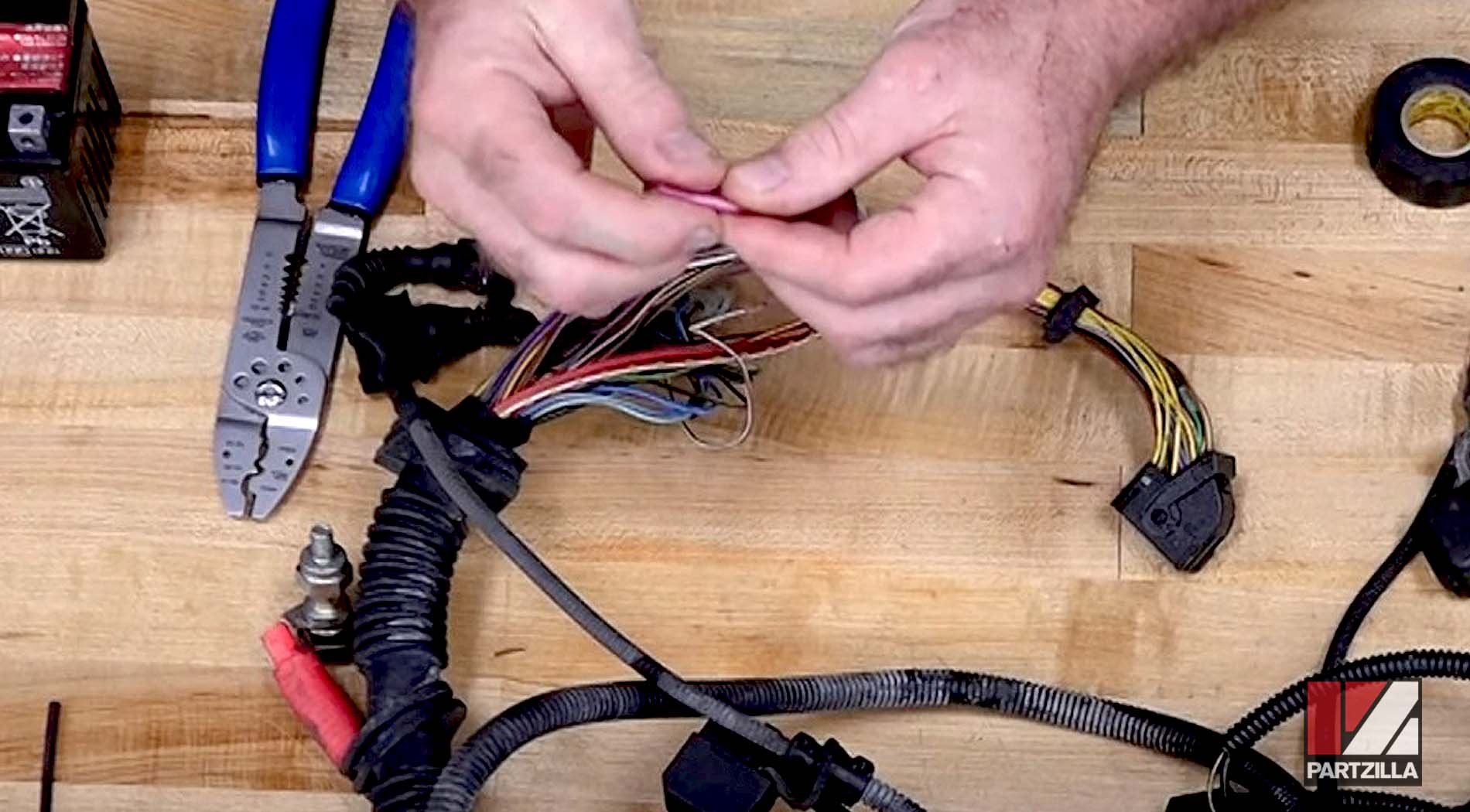

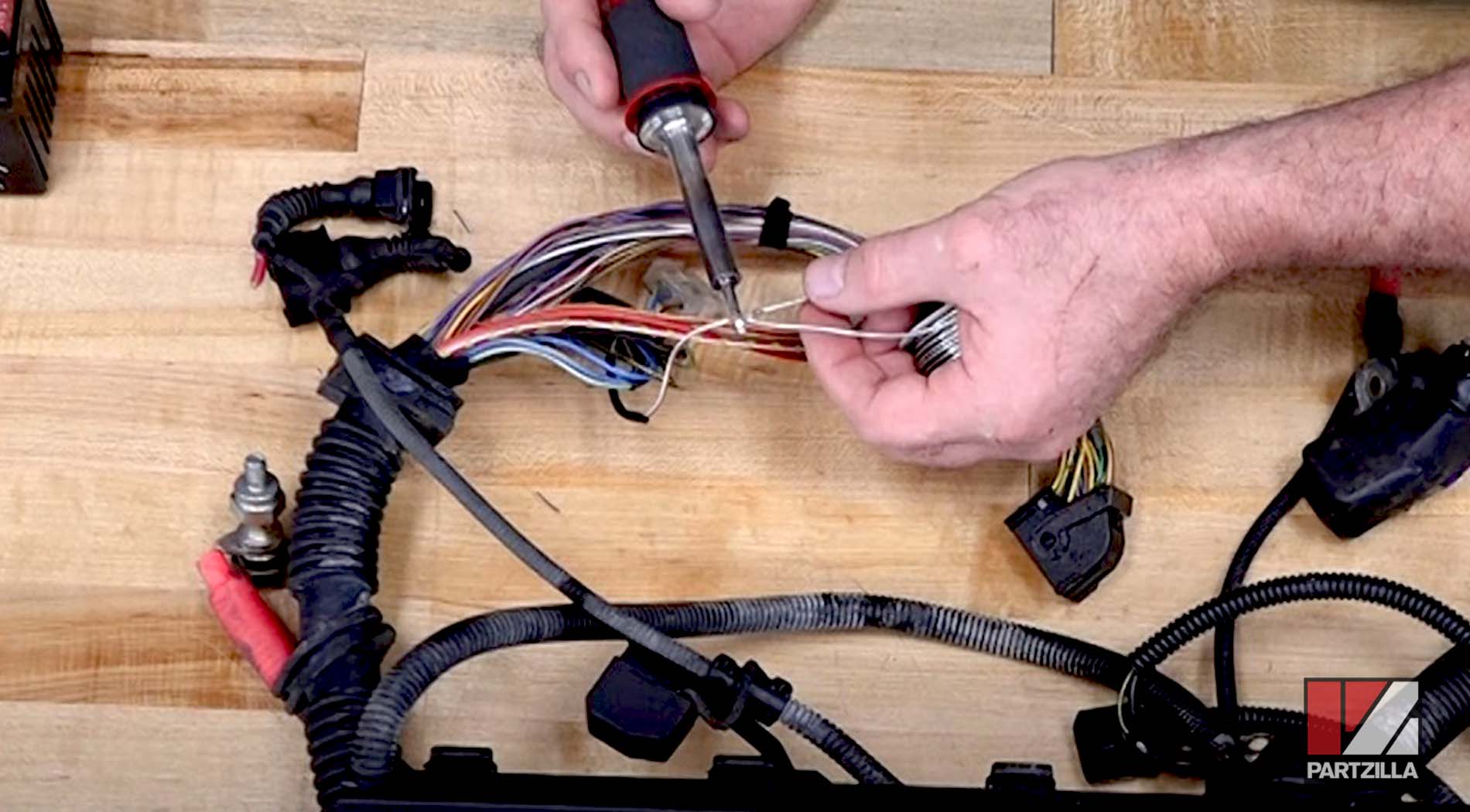

Connections. All connections are weak points in an electrical circuit. Don’t rely on twisting a wire to a connector or to another wire and wrapping the join with electrical tape. The connection won’t be sufficiently strong or waterproof, and will fail sooner or later.

Solution: Solder a wire to a connector or another wire and cover the join with a protective heat shrink tube. If soldering isn’t an option, use a quality connector and crimp it securely to the wire before heat-shrinking it. A strong connection is less likely to fail due to the vibrations motorcycles generate. The heat shrink prevents water from reaching the connection, protecting it from corrosion.

Pivot and pinch points. Wires routed too tightly across areas that experience pivoting or movement (suspension forks, handlebars, etc.) will stretch. Repeatedly or overly stretched wires eventually fray and break. Wires routed through pinch points such as where the seat meets the frame may also get damaged.

Solution: When running wires across pivot points, make sure there’s enough play in the wire to accommodate the movement it will encounter. As for running wires across pinch points, route them at a point where they won’t get squeezed or crushed.

Heat. Never route a wire across a surface that gets hot, such as an engine block’s cooling fins or any part of the exhaust system. Heat melts a wire’s outer jacket and allows the conductive inner wire to short against the nearest piece of metal.

Solution: Route wires as far from heat sources as possible, and use cable ties to hold them away from those heat sources. You can also buy cable sleeving to further protect wires from heat.

Battery Terminals. Corrosion around the battery terminals weakens the current available to the electrical system, while a loose connection at the terminal causes intermittent or complete loss of power.

Solution: Clean the battery terminals at least once a year, and ensure there’s a good metal-to-metal connection between the terminal and the cable. Make sure the terminal and cable are securely tightened together. Coat the terminal/cable connection with dielectric grease to protect it from moisture and prevent future corrosion.

Fuses. Don’t replace a fuse with one with a higher rating. If a particular fuse repeatedly blows, a higher-rated fuse may stop the problem, but it could also lead to a catastrophic fire.

Solution: Always fit the correct amp fuse in its allocated slot in the fuse box. A particular fuse repeatedly blowing is an indication there’s a problem somewhere along that particular circuit, and you should identify and fix the problem as soon as possible.