Thread Restorer vs Tap and Die

If you work on engines long enough, eventually you’ll come across damaged threads or even worse, destroyed threads, which can be a complete nightmare.

At this point, you have some options that might save you from having to buy new engine cases or whatever it is you’re working on, and they come in the form of a tap and die set or a thread restorer (aka thread chaser). So which one should you use? Watch the video above or read on below to learn more about tap and die sets vs thread restorers.

Tap and Die Sets

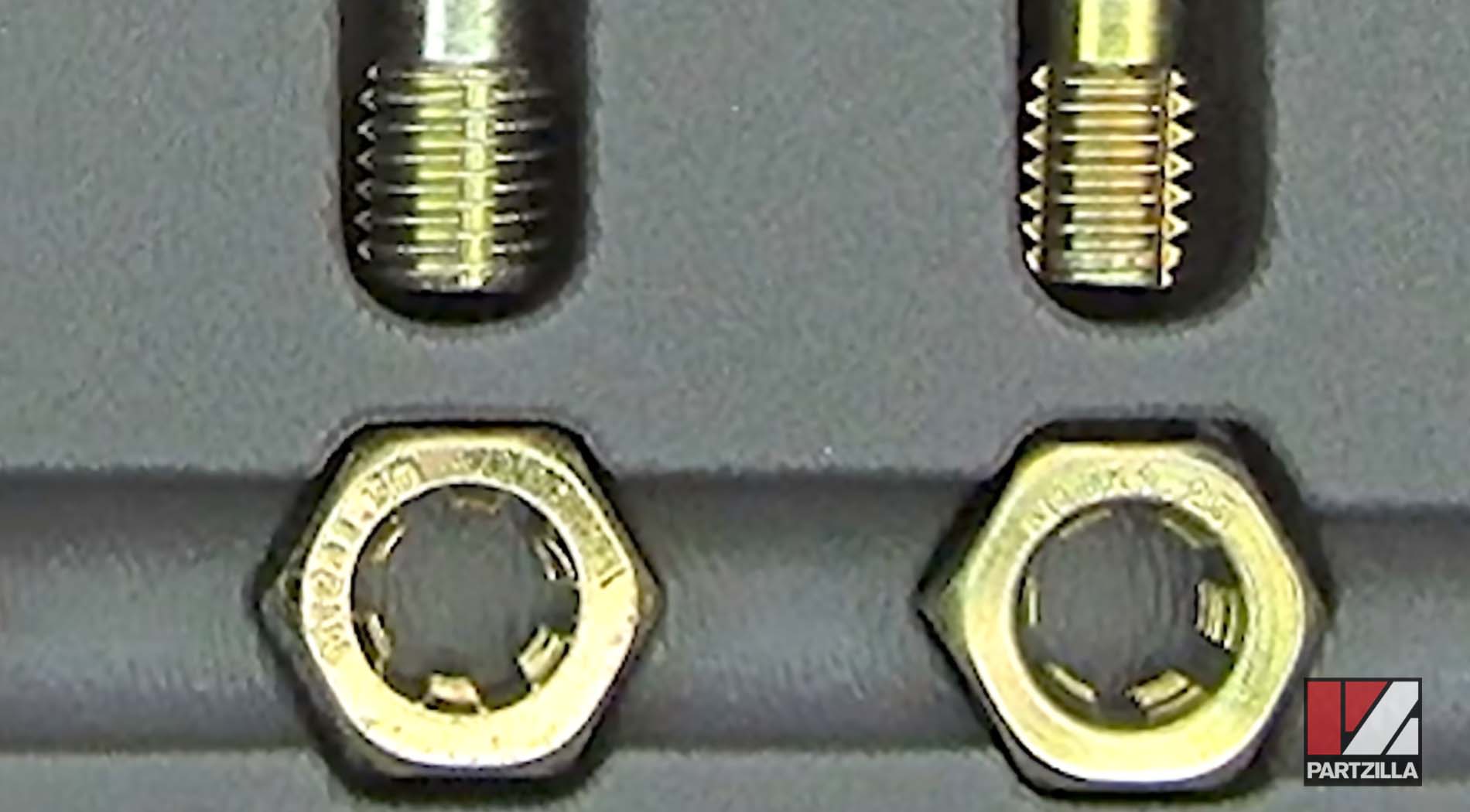

The tap looks like a bolt, but with a very specific design where it has threads and flutes that are cut into and in between each section of thread, of which there are three.

This is designed so any of the debris or corrosion, or whatever material you're trying to cut has a place to go as you’re actually cutting in the new threads. The die straightens out the threads of a bolt and/or a stud. It has those three cutting areas, as well as areas for the debris to fall away as you're cutting or cleaning those threads.

Thread Restorer/Thread Chaser

A thread restorer is built basically the same way. However, the area for the cutaway or the debris is much smaller, giving you a larger area to actually clean out the threads.

This design makes it harder to damage the threads as you’re running it in. Same thing on the die piece as well: much larger surface area for the threads, less cutting area for debris.

Tap and Die vs Thread Restorer: Which to Choose

The biggest difference between the tap and die and the thread restorer is the aggressiveness with which each one does its job.

The tap removes much more material and creates a new thread pattern. For example, if you have a new piece of metal and need to drill and create new threads, the tap is your answer.

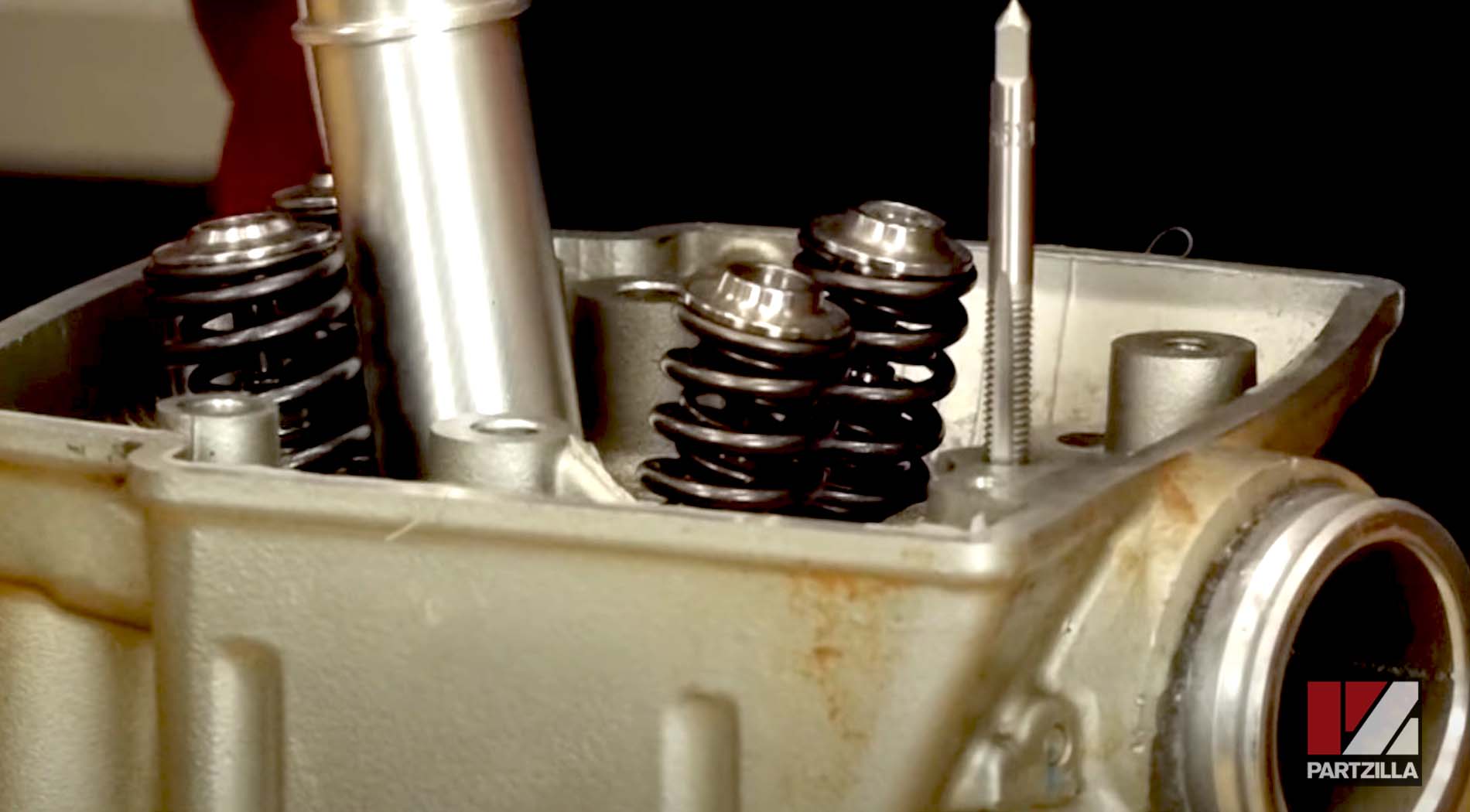

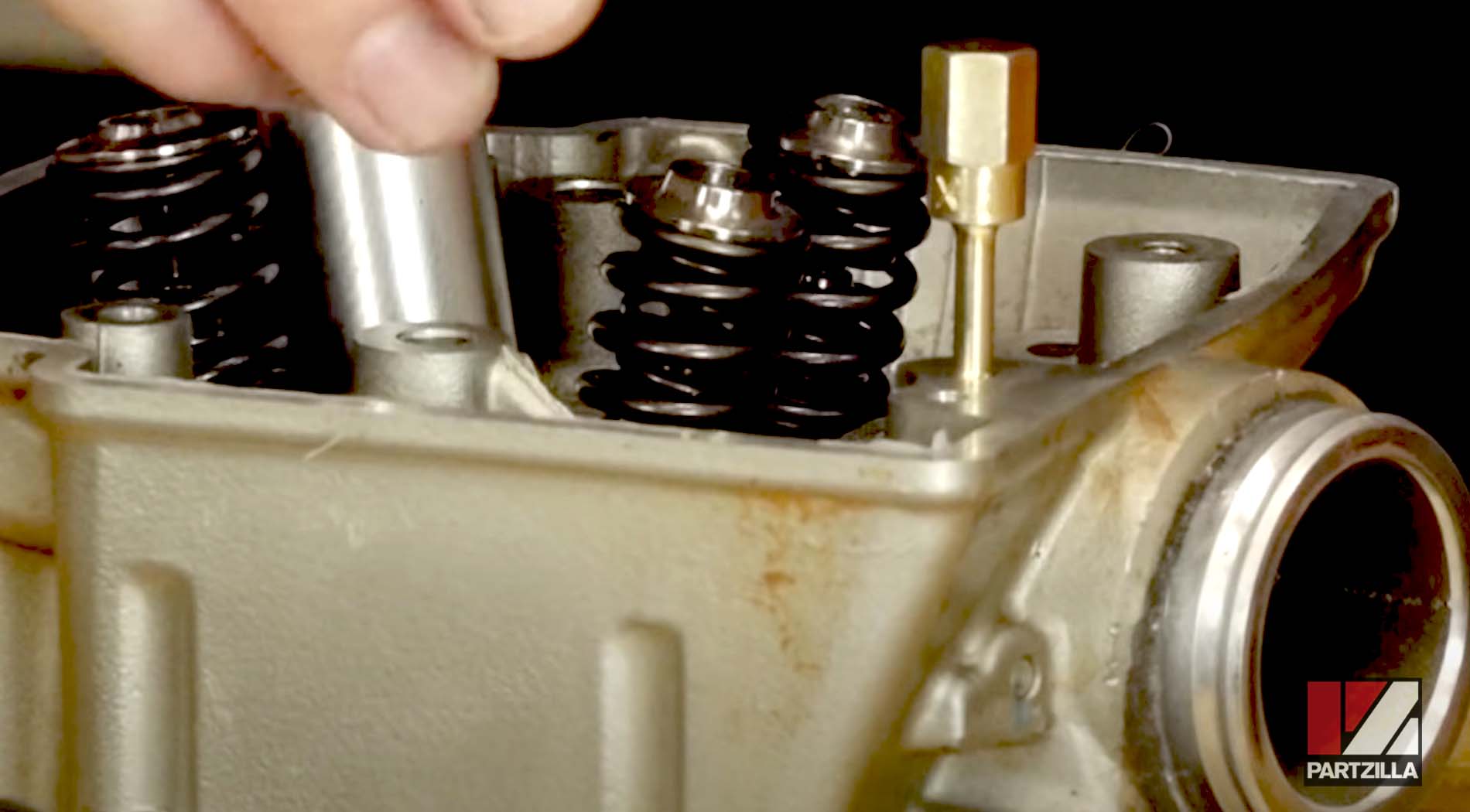

On the other hand, if you’re dealing with corrosion or left-behind threadlocker and you need to clean up the threads to get an accurate torque reading, then the thread restorer is the way to go.

If you look at the tip of the tap itself, you'll notice the bottom edge is chamfered and the distance between the threads is more representative of a drill bit going into the existing threads. The tap takes off more material before it even gets to the cleaning action.

The thread restorer doesn’t have that drill bit-like shape, so it simply cleans threads and removes debris without creating new threads. You can see this if you try to manually insert the tap and the thread restorer into an existing set of threads.

The tap almost immediately meets resistance because of the cutting action, while the thread restorer has a much easier time going into the threads. So a good rule of thumb is unless the threads are really damaged, use the thread restorer to remove debris or threadlocker. For example, if you’re opening up an engine, you’re going to have debris in the threads. Removing that debris allows you to get an accurate torque reading when you put everything back together. It does a minimal amount of damage and removes a minimal amount of material to get the job done.