Should I Take My Powersports Engine to a Machine Shop?

As you go through the process of tearing down an engine, it’s always possible that you’ll reach a point where the parts look questionable, or like something was installed incorrectly.

In this case, we’re talking about parts that might look worn or warped and might not properly mate with the other parts. So what should you be looking for if you’re trying to decide whether to take your engine to a machine shop?

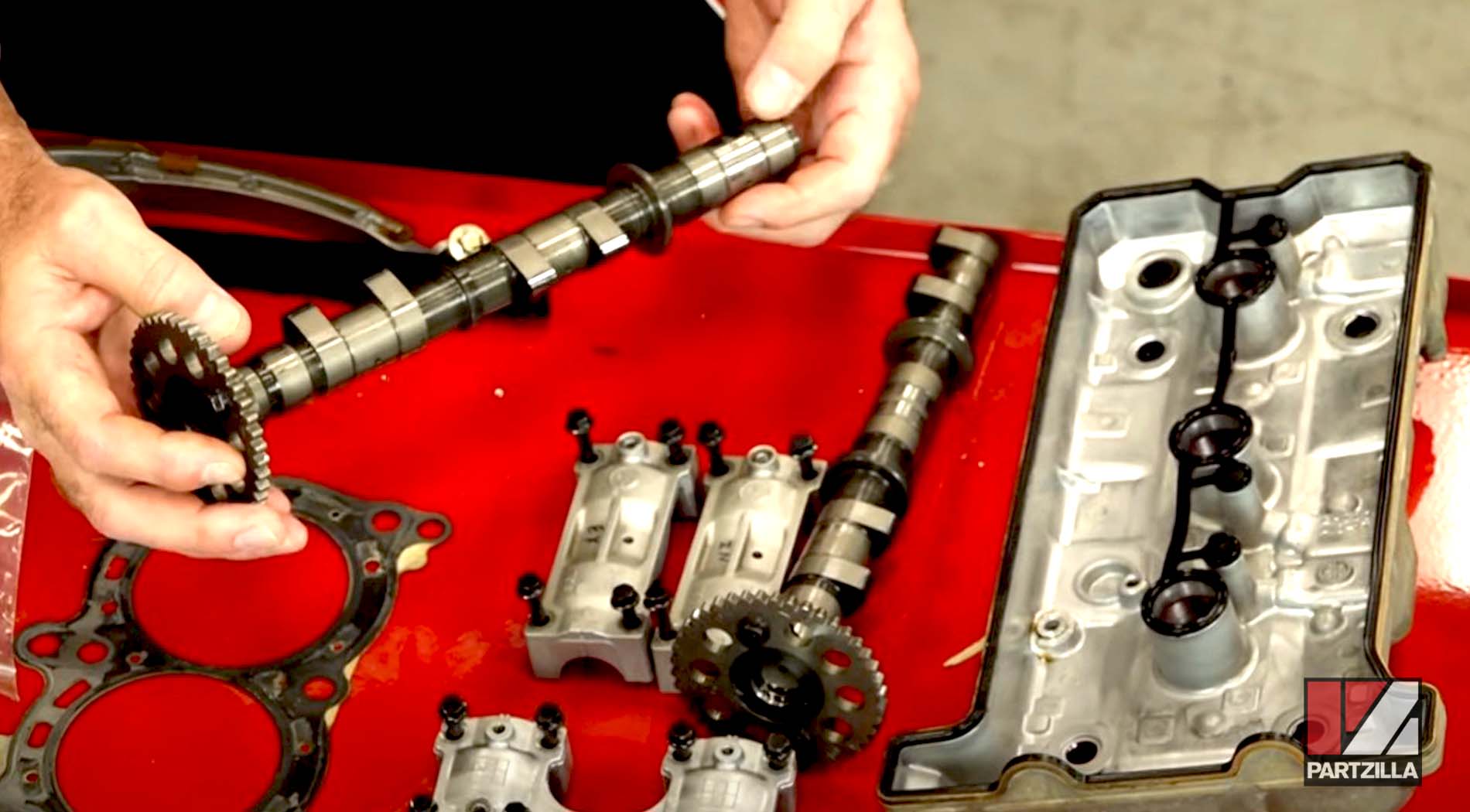

Camshafts

Feel around on the lobes of camshafts with your fingernail. You’re looking for grooves that might be cut into the hard and brittle material of a camshaft. For them to work their best, the lobes need to be smooth. A machine shop can polish cams with an emery cloth to work out any imperfections.

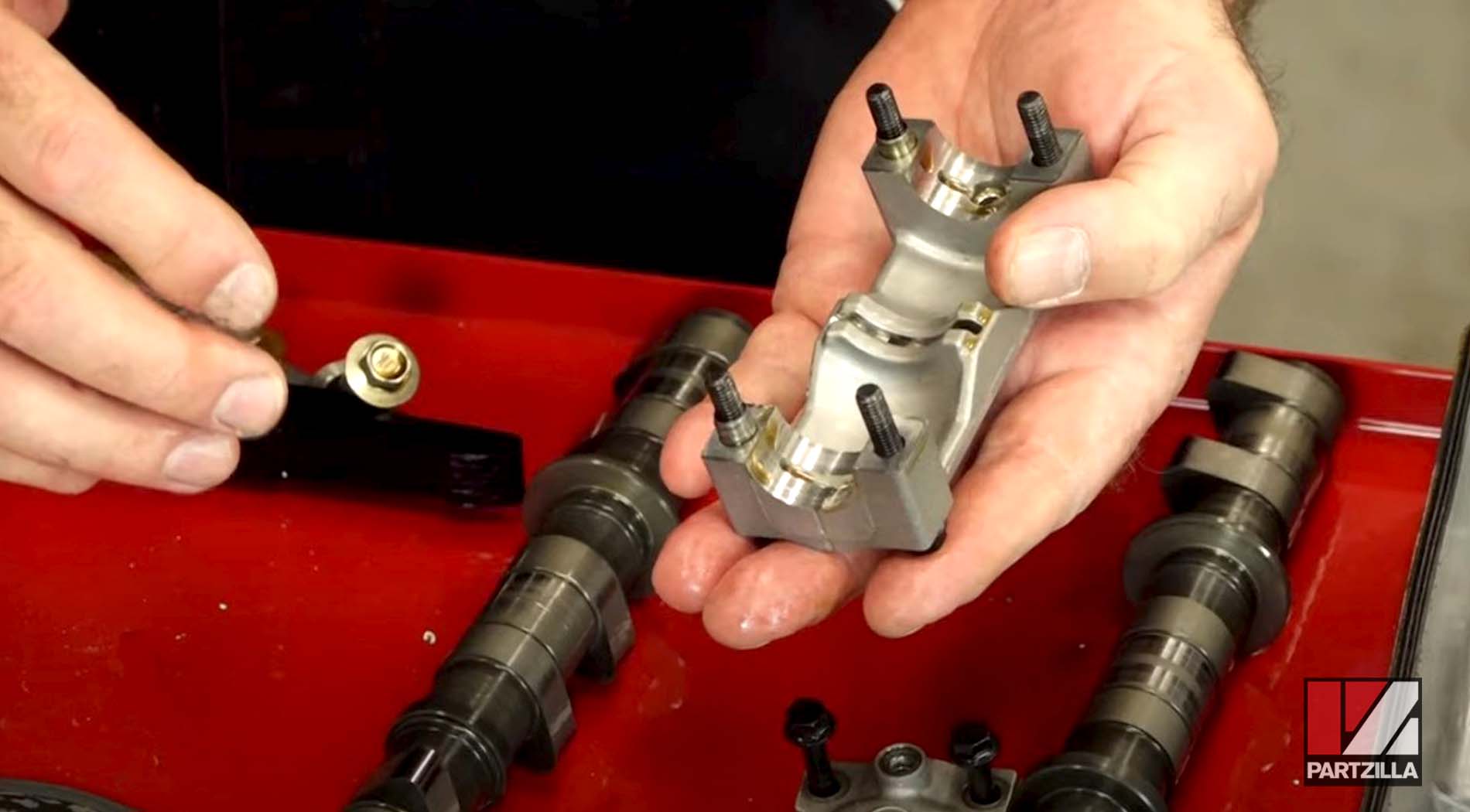

Caps

The caps that hold the cam in place are also a vulnerable component worth inspecting. They can show wear, but what you’re looking for is any scars or gouging on them. The caps are a much softer aluminum than the material used in the cam, so it’s easy to get some damage where these two parts interact.

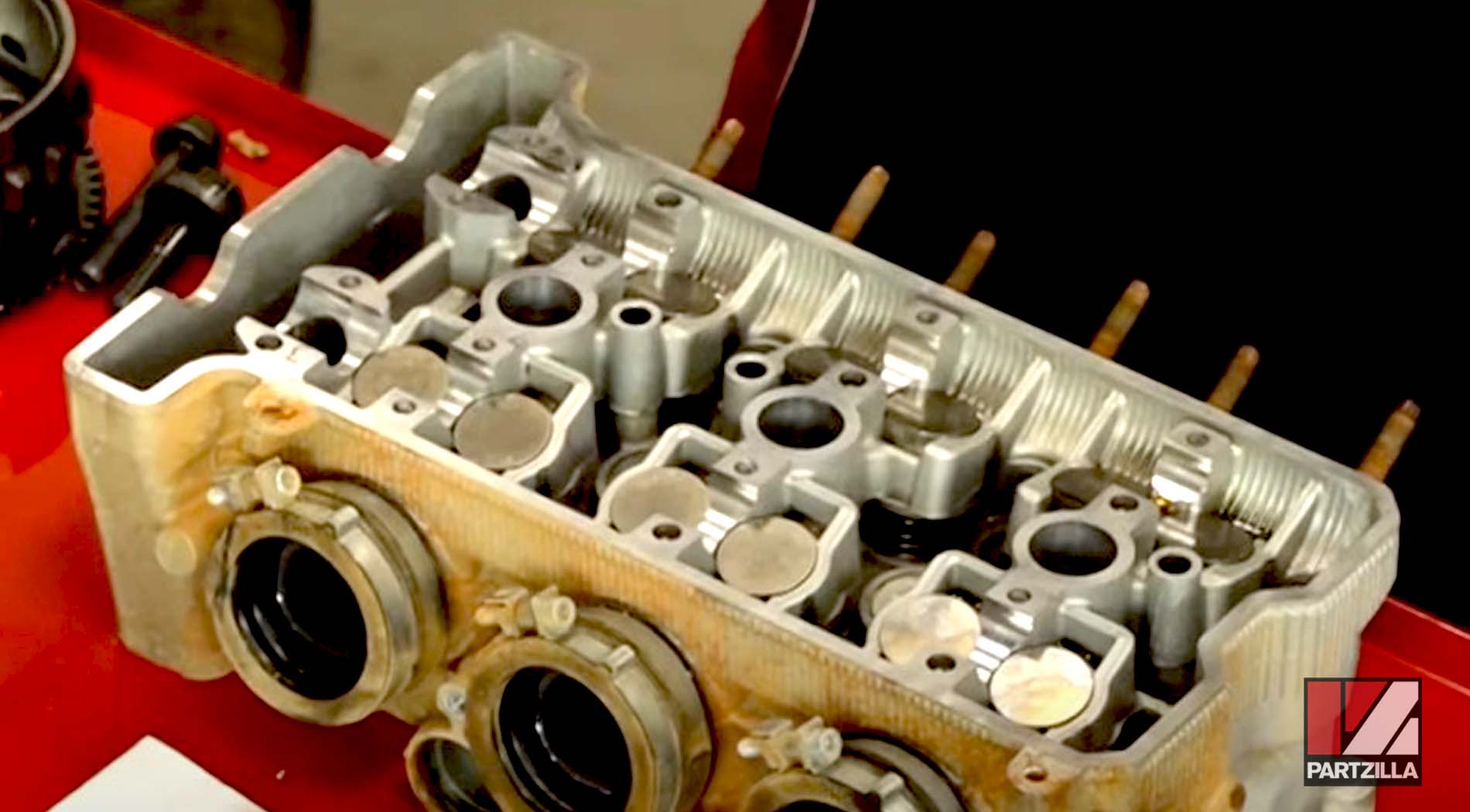

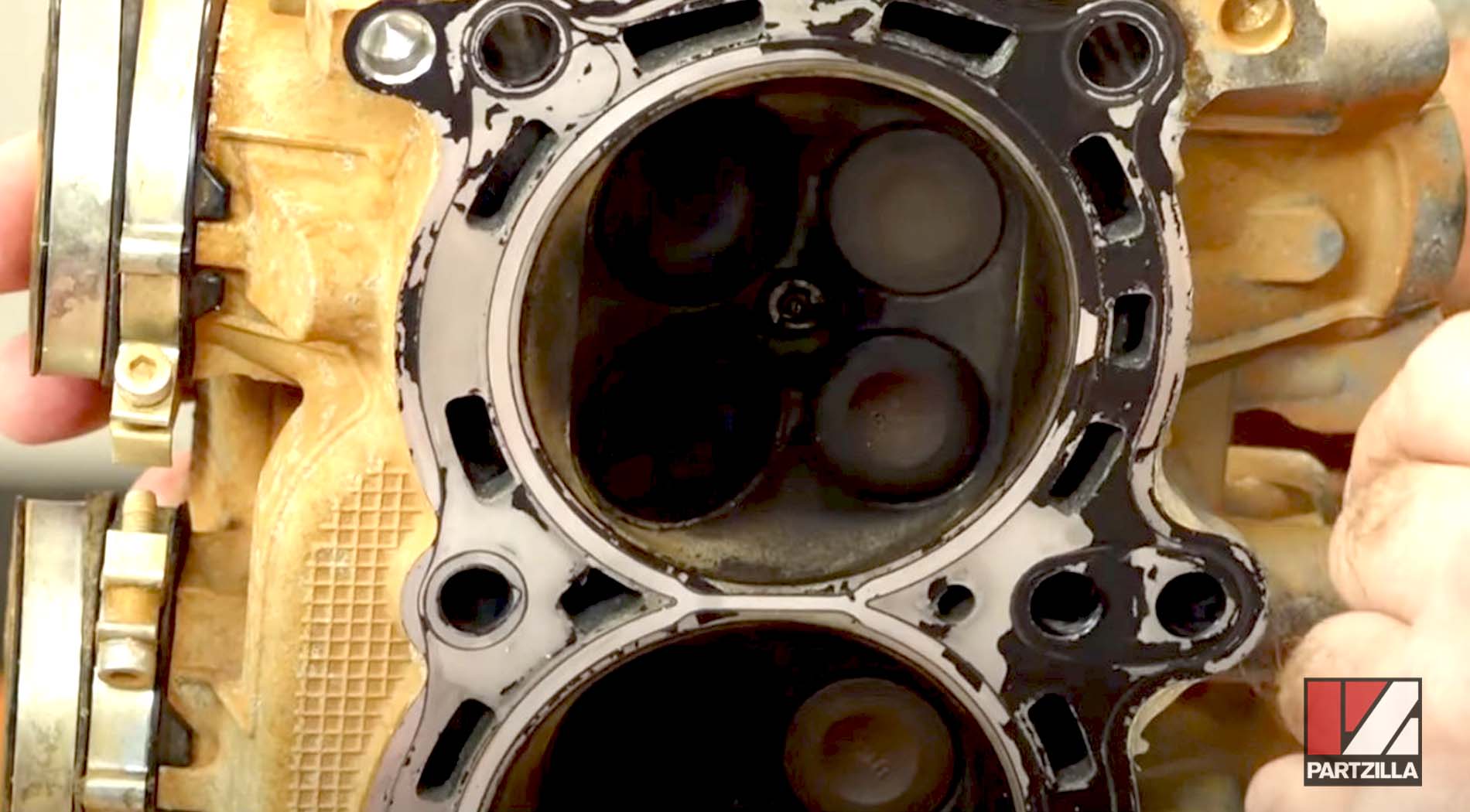

Aluminum Head and Block

This is tough to see with the naked eye, and it’s a place where you might want a machine shop to just look everything over. Even when you loosen bolts in the correct order to de-torque a head from the block, you can still get a warp when you’re taking them apart.

Or the last person might have done it while putting everything together. Either way, these tiny deviations from the flat surfaces required for a good mate between the block and the head can mean trouble for your engine.

A machine shop can use an extremely flat surface and feeler gauges to make sure everything is in spec. If it’s not, they can resurface it. This is the same with the head. Overheating can cause warping, and that will keep the block and head from sealing properly.

Valves

With the valves still in the head, it’s tough to see if the stems are bent. They might even look good when you pull them, but you’ll see them wobbling if they roll across your workbench when they’re bent. A machine shop can look at them and pick up bends that you might not even be able to see on your table.

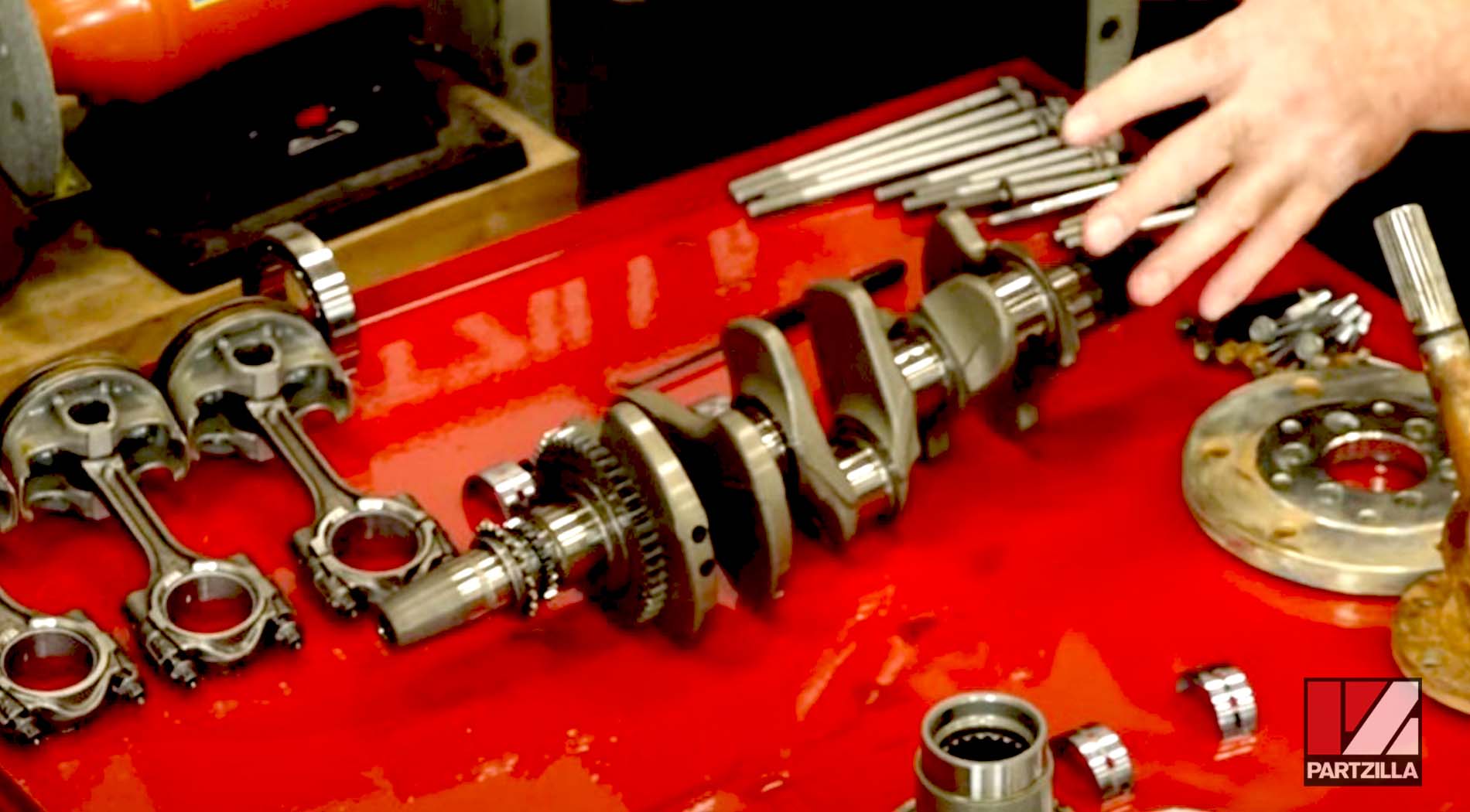

Crank

You can see significant damage and deformities with the naked eye on the crank, but some stuff is just too hard to see. The crank can be twisted and you might not even notice. A machine shop can use a lathe and rotate the crank, and make sure it’s in spec before you put it back in the motor.

Machine Shop Expense

If you’re going to build an engine, it should hold together for a long time. When things aren’t correct — a bad seal between the block and head; a bent valve; a twisted crank; etc. — the damage could lead to a catastrophic failure. And that just means more expense in both parts and time to get the job done right. In the end, a little added expense to have a professional machine shop check out components can save you some time and money in the long run.

If you're curious about what a complete do-it-yourself engine build looks like and how much work goes into it, watch the video above to see our complete Yamaha Raptor ATV engine build.